Table of Contents

ToggleIntroduction

PVC panels for ceilings have become one of the most widely chosen interior finishing solutions around the world. From residential homes and commercial spaces to industrial warehouses and public buildings, PVC ceiling panels deliver an attractive, durable, and cost-effective alternative to traditional materials like gypsum board, wood, and metal. For buyers — especially wholesalers, contractors, and importers — understanding PVC ceiling panel pricing is critical to making smarter sourcing decisions.

In this comprehensive guide, we’ll explore PVC ceiling panel prices with a deep comparison between factory direct pricing and market/retail rates. We’ll break down the key factors that influence cost, regional pricing differences, installation and logistics cost considerations, quality and specification impacts, and practical tips for negotiation and procurement.

By the end of this article, you’ll have a 360° understanding of how PVC ceiling panel pricing works — and how you can leverage that knowledge to improve profits, reduce risk, and secure the best deals.

What Are PVC Ceiling Panels and Why They Matter

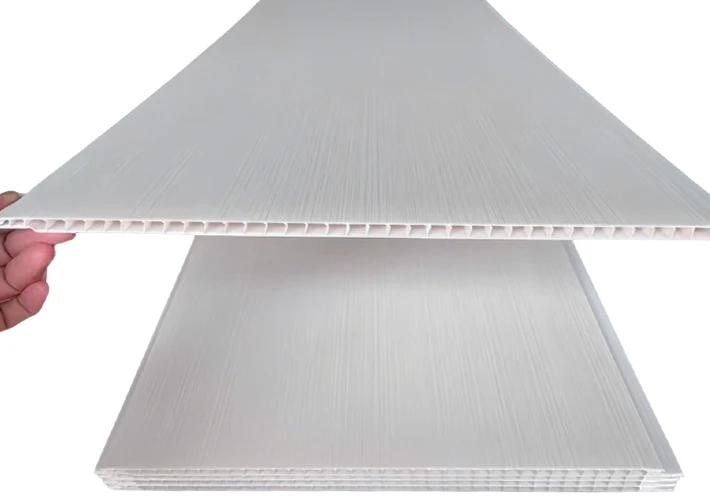

PVC (Polyvinyl Chloride) ceiling panels are engineered plastic panels manufactured through extrusion or calendaring processes. They are lightweight, water-resistant, termite-proof, and available in various surface finishes, including wood grain, marble texture, gloss, matte, perforated acoustic types, and more.

Key Advantages of PVC Ceiling Panels

Water and Moisture Resistance

PVC panels are highly resistant to humidity and moisture damage, making them ideal for bathrooms, kitchens, basements, and humid climates.

Low Maintenance

Easy to clean with soap and water. No need for repainting or sealing.

Lightweight and Easy to Install

Compared to gypsum, wood, and metal ceilings, PVC panels are lighter and install faster — often reducing labor costs.

Aesthetic Flexibility

Modern printing and finishing technologies allow PVC panels to mimic natural wood, stone, and metallic finishes at a fraction of the cost.

Longevity and Durability

High-quality PVC panels can last 10–25 years or more without yellowing, cracking, or warping.

Because of these benefits, PVC ceiling panels are widely used in homes, offices, hotels, hospitals, schools, commercial buildings, factories, and even outdoor patios where appropriate.

Understanding PVC Ceiling Panel Pricing Basics

Before comparing factory and market pricing, it’s important to define the common pricing units used in the industry:

| Pricing Term | Meaning |

|---|---|

| USD/m² | Price per square meter — most common for international contracts |

| USD/pcs | Price per individual panel piece |

| CIF/CFR | Cost including shipping to port (import cost) |

| EXW | Factory price excluding shipping and export costs |

| MOQ | Minimum Order Quantity required by supplier |

PVC ceiling panel pricing is influenced by multiple dimensions:

- Panel Thickness (e.g., 5mm, 8mm, 10mm+)

- Panel Width & Length

- Surface Finish (printed vs plain, embossing, gloss)

- Acoustic or Specialty Designs (perforated, insulated)

- Quality and Brand Reputation

- Order Volume (MOQ)

- Shipping and Packaging

Let’s dive into how these elements affect pricing.

Factory Direct Prices vs Market (Retail/Distributor) Rates

PVC ceiling panel prices differ significantly depending on where you buy them. The two main purchasing channels are:

A. Factory Direct Prices

“Factory price” refers to the cost of PVC ceiling panels when purchased directly from the manufacturer, usually in large quantities.

Advantages of Factory Pricing:

- Lower Unit Cost — No middleman markup

- Flexible Customization — Length, color, thickness, logos

- Factory Warranty and Support

- Stable Quality Control

Typical Price Range (Factory Direct)

Note: Prices below are approximate average ranges and can vary by region, specification, and quantity.

| Specification | Approx. EXW Factory Price (USD/m²) |

|---|---|

| Basic White PVC | $1.20 – $1.80 |

| Printed Woodgrain | $1.80 – $2.50 |

| Marble/High-Gloss | $2.50 – $3.20 |

| Acoustic Perforated Panels | $3.20 – $5.00+ |

Why Factory Prices Are Lower

- No Middleman Markups: Distributors, wholesalers, and retailers often mark up prices by 10-30% or more.

- Bulk Production Efficiency: Large orders reduce per-unit cost.

- Direct Export Terms: EXW pricing avoids additional handling at ports and warehouses.

B. Market/Retail Prices

Retail or distributor prices refer to PVC panels sold by dealers to end customers, renovation companies, or small contractors.

Typical Market Price Range:

| Specification | Approx. Market Price (USD/m²) |

|---|---|

| Basic PVC Panels | $1.80 – $2.50 |

| Decorative Printed Panels | $2.50 – $3.50 |

| Premium Marble/Glossy | $3.50 – $4.50 |

| Acoustic or Specialized Panels | $4.50 – $7.00+ |

Why Retail Prices Are Higher

- Layered Profit Margins: Each intermediary adds markup.

- Local Taxes & Warehouse Costs: Stocking inventory increases cost.

- Smaller Order Quantities: Smaller shipments mean higher per-unit costs.

Example: If a factory sells PVC panels at $2.10/m² EXW and a distributor sells at $2.80/m² retail, the middleman markup has increased the price by ~33% before reaching the end buyer.

What Affects PVC Ceiling Panel Prices

Now let’s break down the specific factors that impact pricing in detail.

A. Material Thickness and Density

Thicker panels use more raw material and provide better durability, stability, and a higher quality feel.

- Slim Panels (5-7mm): Lower cost, lighter weight

- Standard Panels (8-10mm): Balanced performance & price

- Heavy Duty (12mm+): Premium feel, higher price

B. Surface Finish

Plain white panels are cheapest. Printed or laminated patterns require extra processing:

- Plain White: Lowest cost

- Wood Grain / Stone Pattern: Mid-range

- High Gloss / Metallic / Custom Prints: Premium price

C. Acoustic or Specialty Features

Panels with perforations, sound absorption backing, integrated lighting channels, or fire-retardant additives cost more due to extra materials and manufacturing steps.

D. Panel Width and Length

Wider and longer panels cover more area per piece, reducing installation time but potentially increasing unit cost.

E. Order Quantity (MOQ)

Factory pricing depends heavily on MOQ. Typical MOQs:

- Small Orders: Higher per-unit cost

- Medium (500-1000 m²): Lower

- Large (2000+ m²): Best pricing

Bulk orders unlock deeper discounts.

F. Packaging and Shipping Costs

- Standard Packaging: Cheapest

- Export-Ready Wooden Crates: Higher price

- Customized Packaging (Branded Boxes): Premium

Shipping, port fees, customs, and inland freight also influence landed cost.

Regional Pricing Differences

PVC ceiling panel prices vary across regions due to differences in raw material costs, labor costs, currency exchange rates, and trade policies.

A. China

China is the largest global exporter of PVC panels. Major manufacturing hubs are in Foshan, Shanghai, Ningbo, Qingdao, and Guangzhou.

- Factory Pricing: Very competitive

- Export Infrastructure: Mature sea freight options

- MOQ Flexibility: Many factories accept medium to large orders

Typical EXW prices in China are usually the most competitive globally.

B. Southeast Asia

Thailand, Vietnam, Malaysia, and Indonesia have growing PVC panel industries. Local pricing may be slightly higher than China but with shorter lead times to nearby markets.

C. Europe & North America

Local manufacturing exists but at higher cost due to labor and regulation. Importing from Asia is common for competitive pricing.

D. Middle East & Africa

Often dependent on imports. Prices include high shipping costs, but regional distributors stock products to balance availability with cost.

How to Compare Factory Quotes Effectively

When requesting quotes from PVC panel factories, it’s important to ensure apples-to-apples comparisons.

Checklist for Quote Comparison

✔ Material Specification: thickness, finish, core density

✔ Panel Dimensions: width, length, coverage per piece

✔ Finish Type: flat, printed, embossed

✔ MOQ Requirements

✔ Packaging Details

✔ Lead Time

✔ Export Terms: EXW, FOB, CIF, DDP

✔ Quality Assurance & Warranty

Ask suppliers to provide sample boards to evaluate print quality, edge finishing, and color consistency.

Installation & Additional Costs to Consider

Price of material is only part of the budget. Installation and related costs can significantly impact total expenditure.

A. Installation Labor

PVC panels install faster than gypsum or wood, but labor costs remain regionally variable. Installers may charge per m² or per job.

B. Accessories and Profiles

Ceiling systems require:

- PVC or Aluminum Frames

- Edge Trims

- Connectors and Clips

- Lighting Channels

These add to the total cost.

C. Transportation and Handling

Whether importing or local delivery, transportation adds based on weight, volume, and distance.

If importing:

- Shipping (Sea/Air)

- Insurance

- Port Fees

- Customs Duties & VAT

- Local Delivery

These costs are often overlooked but critical for exact landed pricing.

Tips to Get the Best PVC Ceiling Panel Prices

Whether you’re an importer, contractor, or bulk buyer, here are practical tips to secure better pricing:

1.Buy Direct from Factory

Eliminate retail markups whenever possible.

2.Consolidate Orders

Larger orders reduce per-unit cost and shipping cost per square meter.

3.Negotiate FOB/CIF Terms

If you handle logistics, negotiate favorable FOB or CIF terms.

4.Lock in Multi-Year Supply Deals

Commit to more volume for better pricing stability.

5.Compare Multiple Suppliers

Don’t settle for the first quote — evaluate at least 3–5 qualified factories.

6.Ask for Free or Low-Cost Samples

Evaluate quality before confirmation.

7.Know Local Cost Benchmarks

Understand typical market rates in your region to avoid overpaying.

Conclusion

PVC ceiling panels are a cost-effective, high-performance option across many interior applications, and pricing varies widely depending on source, quality, specification, and volume. Understanding factory direct pricing versus market rates is essential for smart purchasing decisions.

In general:

- Factory pricing offers the lowest unit cost, customization, and flexibility — especially for bulk buyers.

- Market/retail pricing suits smaller orders or local availability but comes with markup.

- Total cost of ownership includes accessories, installation, logistics, and taxes — not just the material price itself.

Ultimately, knowing the true cost dynamics empowers you to negotiate smarter, reduce project costs, and improve profitability — whether you’re a contractor, importer, distributor, or end buyer.