When selecting the right thickness for WPC (Wood Plastic Composite) wall panels, several factors need to be considered to ensure optimal performance, durability, and aesthetic appeal. One of the most important aspects of WPC panels is their ability to withstand various environmental conditions, especially temperature fluctuations, humidity, and direct exposure to sun or rain. Additionally, the intended use—whether for residential, commercial, or industrial purposes—also plays a crucial role in determining the right thickness.

This article will delve into the factors that should influence your WPC wall panel thickness selection based on climate and usage conditions, helping you make an informed decision for your project. From tropical climates to cold and dry environments, there are key considerations that will guide you towards the best option for long-lasting, efficient, and aesthetically pleasing results.

Table of Contents

Toggle1.Understanding WPC Wall Panels

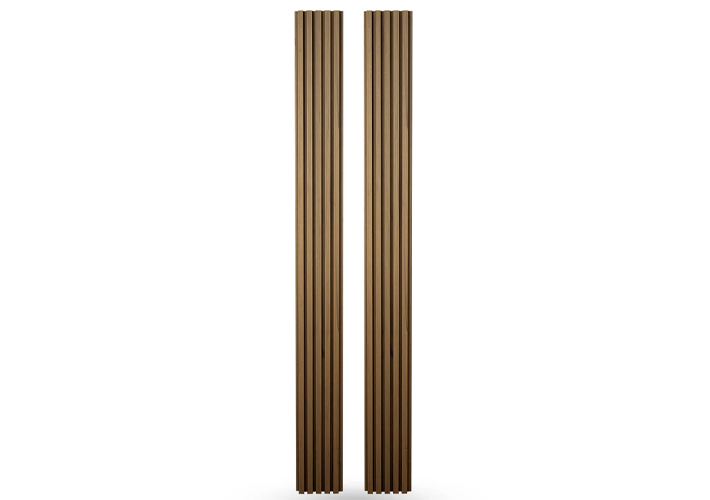

WPC wall panels are made by combining wood fibers with plastic, creating a composite material that offers the best of both worlds. This material is resistant to the typical issues faced by natural wood, such as rot, warping, and insect damage, while maintaining the aesthetic qualities of wood. WPC wall panels are widely used in both interior and exterior applications, from cladding to fences, to creating modern and sustainable architectural designs.

WPC wall panels are available in various thicknesses, which impact their strength, durability, insulation properties, and cost. Selecting the correct thickness is crucial to ensure that the panels meet the performance requirements for specific climate conditions.

2.Climate Considerations for WPC Wall Panels

WPC panels are designed to withstand a variety of environmental conditions. Here’s a breakdown of how different climates impact the thickness choice:

2.1 Hot and Humid Climates

Regions with hot and humid climates, such as Southeast Asia or coastal areas, can impose unique challenges for building materials. Excessive moisture in the air can lead to expansion, contraction, or even warping of panels that are not properly designed or installed.

Recommended Thickness:

- 8mm to 12mm thickness is ideal for such climates, as these panels provide sufficient rigidity while also resisting warping or expansion caused by high humidity.

- Thicker panels provide added stability and help to maintain the panel’s shape, reducing the risk of deformation from constant exposure to moisture.

- In humid environments, thicker panels can also help with insulation, providing an added layer of protection against heat penetration.

Additional Considerations:

- Look for WPC panels that are specifically treated to resist mold and mildew growth, as humidity can encourage fungal development.

- Ensure proper ventilation in the installation area to reduce moisture buildup that can affect the panels’ integrity over time.

2.2 Cold and Dry Climates

Cold climates, such as those found in northern regions or mountainous areas, pose different challenges for materials. The dry air and freezing temperatures can cause materials to shrink or crack if they are not resilient enough to handle thermal stress.

Recommended Thickness:

- 12mm to 16mm thickness is recommended for cold climates. The increased thickness helps to provide additional strength to the panels and ensures that they do not become brittle during freezing conditions.

- In areas with heavy snowfall, thicker panels are less likely to warp or crack due to the weight of accumulated snow.

Additional Considerations:

- Thicker panels provide enhanced thermal insulation, reducing energy consumption for heating systems in buildings.

- It is important to choose WPC panels with a higher density in these climates, as they will have better resistance to cold and lower rates of contraction.

2.3 Hot and Dry Climates

Regions with hot, dry climates, such as parts of the Middle East or southwestern United States, experience extreme temperatures, often exceeding 100°F (38°C) in summer. The heat can cause materials to expand, while the dry conditions can lead to cracking and fading if the materials aren’t suitable.

Recommended Thickness:

- 10mm to 14mm thickness is ideal for dry, hot climates, providing a balance between heat resistance and structural integrity.

- Thicker panels are better at withstanding the effects of high temperatures and UV exposure, reducing the likelihood of fading and deterioration over time.

- UV protection coatings or additives in WPC panels are essential in such climates to maintain the material’s appearance and prevent degradation from constant sun exposure.

Additional Considerations:

- Choose panels with UV inhibitors to maintain the integrity and color of the panels in extreme sun exposure.

- Ensure that the installation is done with proper sealing to prevent moisture from entering the panels, which could lead to cracking in dry conditions.

2.4 Temperate Climates

Temperate climates, characterized by moderate weather conditions with distinct seasons, such as parts of Europe, the Pacific Northwest, or coastal areas, have less extreme temperature fluctuations but still experience changes in humidity and precipitation.

Recommended Thickness:

- 8mm to 12mm thickness is generally sufficient for temperate climates. These regions don’t experience the same extreme conditions as other areas, so standard thickness options are typically adequate.

- In regions with seasonal temperature changes, it’s important to choose panels with a balanced thickness that can handle moderate fluctuations in humidity and temperature.

Additional Considerations:

- Ensure that the panels are resistant to both heat and cold to avoid issues with expansion or contraction.

- Regular maintenance of the panels, such as cleaning and resealing, will extend the life of the WPC wall panels in moderate climates.

3.Usage Conditions and Panel Thickness

Besides the climate, the intended use of the WPC wall panels is another critical factor in determining the optimal thickness.

3.1 Residential Applications

For residential applications, the wall panels are often used for aesthetic purposes, interior walls, or exteriors like fences and cladding. The thickness needed will depend on whether the panels are exposed to the elements or located indoors.

Recommended Thickness:

- 8mm to 12mm for indoor applications and moderate exterior use.

- 12mm or more for areas exposed to harsher environmental conditions, such as exterior walls or areas where extreme weather is common.

3.2 Commercial and Industrial Applications

In commercial and industrial settings, WPC wall panels must endure higher levels of wear and tear, including more frequent exposure to the elements, heavy foot traffic, or industrial machinery.

Recommended Thickness:

- 12mm to 16mm thickness is recommended for commercial and industrial applications, as they offer greater durability and structural integrity, capable of withstanding more rigorous use.

- Thicker panels are also better at providing noise insulation and privacy in commercial spaces like offices, hotels, and restaurants.

3.3 Cladding and Facades

WPC panels are often used as cladding for building facades due to their weather-resistant properties and ability to mimic the look of wood. The thickness of the panels will depend on the height and exposure to the elements.

Recommended Thickness:

- 12mm to 16mm for cladding and facades, as these panels are exposed to wind, rain, and sun. Thicker panels will be more resilient and provide better insulation for the building.

- For high-rise buildings or areas with heavy wind loads, thicker panels are preferred to prevent damage.

4.Factors Affecting WPC Panel Thickness Choice

While climate and usage conditions play significant roles in determining the right thickness, other factors should also be considered:

4.1 Structural Support

The structural support provided by the wall or frame to which the panels will be attached is an important consideration. Thicker panels require more substantial support, while thinner panels may suffice with lighter framing.

4.2 Panel Finish and Aesthetics

If the primary goal is aesthetic appeal, the thickness of the panels may be chosen based on how they contribute to the overall design. For instance, thicker panels might offer a more robust, luxurious appearance, whereas thinner panels could be used for a sleek, modern look.

4.3 Budget and Cost

Thicker WPC panels typically come at a higher price due to the additional materials and manufacturing processes involved. Balancing the required thickness with the available budget is crucial for many projects, especially large-scale commercial or industrial uses.

5.Future Development Trends for WPC Wall Panels

As sustainability and technology continue to shape the construction and building materials industry, the future of WPC (Wood Plastic Composite) wall panels is expected to evolve significantly. Several trends are emerging that could influence how WPC panels are produced, used, and designed in the coming years. Below are some of the key future development trends for WPC wall panels:

5.1 Sustainability and Eco-Friendly Innovations

As the construction industry increasingly focuses on sustainable building practices, WPC wall panels are well-positioned to become an even more attractive option due to their inherent eco-friendly properties. Moving forward, there will be continued emphasis on reducing the environmental impact of WPC panels in terms of raw material sourcing, manufacturing processes, and end-of-life disposal.

Key Developments:

- Recycled Materials: The use of recycled plastics and wood fibers is expected to increase, helping to reduce the reliance on virgin resources. WPC panels could evolve to include a higher percentage of recycled materials, further reducing their carbon footprint.

- Biodegradable and Non-Toxic Additives: Manufacturers are likely to explore more environmentally friendly additives and coatings, reducing the use of harmful chemicals in the production of WPC panels.

- Closed-Loop Recycling: The potential for closed-loop recycling systems will grow, where WPC panels can be reused or recycled at the end of their lifespan, further minimizing waste.

Impact on Panel Thickness:

- As sustainable practices take precedence, thinner panels made from recycled materials could become more common, though they will still need to meet the same durability and performance standards. Innovations in material science may also allow for stronger, thinner panels, reducing both the material usage and overall costs.

5.2 Advances in Technology and Manufacturing Processes

The future of WPC wall panels will be heavily influenced by technological advancements, from new production techniques to enhanced design capabilities. These developments will allow manufacturers to produce more durable, versatile, and customized WPC panels that meet the needs of various climate and usage conditions.

Key Developments:

- 3D Printing: The adoption of 3D printing technology could lead to more customizable designs and geometries for WPC wall panels. This technology allows for faster prototyping and more intricate patterns, which could become increasingly important in architectural applications.

- Nano-Coatings and Smart Materials: The integration of nano-coatings can enhance the resistance of WPC panels to scratches, stains, UV degradation, and moisture. Additionally, smart materials embedded with sensors could monitor the condition of the panels and provide real-time data on environmental conditions or wear-and-tear.

- Automation and AI: Advanced manufacturing techniques powered by AI and automation will likely lead to more precise, consistent, and cost-efficient production of WPC panels. AI can be used to optimize panel thickness and material composition based on specific project requirements.

Impact on Panel Thickness:

- As these technologies advance, manufacturers may be able to produce thinner panels that maintain or even improve upon the durability and strength of current options. Innovations in material bonding and structure could lead to lightweight yet robust panels that deliver superior performance at a lower cost.

5.3 Improved Thermal and Acoustic Insulation Properties

One of the primary advantages of WPC wall panels is their ability to provide excellent insulation. However, as the demand for energy-efficient buildings and improved indoor comfort continues to rise, WPC panels are expected to further evolve to meet these needs. Manufacturers will focus on enhancing the thermal and acoustic performance of WPC panels, making them suitable for a broader range of applications.

Key Developments:

- Enhanced Thermal Insulation: The development of new composite materials and manufacturing techniques will improve the heat-insulating properties of WPC panels, allowing buildings to maintain comfortable temperatures while reducing the need for heating and cooling. This will be especially beneficial in regions with extreme temperature fluctuations.

- Acoustic Performance: WPC panels with enhanced soundproofing capabilities will become more popular, particularly in commercial and residential applications where noise reduction is essential. Manufacturers are likely to incorporate additional layers or specialized materials to improve the sound insulation properties of WPC panels.

Impact on Panel Thickness:

- To improve both thermal and acoustic performance, thicker WPC panels may become more common in future designs. However, manufacturers will also look at integrating lightweight materials with high insulating properties to offer the same benefits in thinner, more cost-effective panels.

5.4 Modular and Prefabricated Systems

With the growing trend of modular and prefabricated construction, WPC wall panels are expected to play a key role in this movement. These construction methods allow for faster and more efficient building processes, and WPC panels are a suitable choice due to their ease of installation, durability, and low maintenance.

Key Developments:

- Prefabricated Wall Systems: WPC panels will increasingly be manufactured as part of prefabricated wall systems, which can be easily transported and assembled on-site. These modular systems will speed up construction timelines and reduce labor costs.

- Interlocking Panels: WPC panels with interlocking systems will become more prevalent, making installation faster and easier. This will particularly benefit large-scale commercial and residential projects where speed of installation is a priority.

Impact on Panel Thickness:

- Prefabricated and modular systems often require standardized thicknesses for efficiency in manufacturing and installation. As these systems evolve, manufacturers may standardize panel thickness to improve the speed of production while ensuring that the panels continue to meet the required strength and insulation standards.

5.5 Aesthetic Customization and Design Flexibility

The aesthetic appeal of WPC wall panels has always been one of their strongest selling points, and this trend is expected to continue into the future. As architects and designers push for more creative and diverse building designs, WPC panels will be increasingly tailored to meet these demands.

Key Developments:

- Variety in Textures and Finishes: WPC panels will continue to offer a wide range of textures, from wood grain to stone and marble finishes. New technologies may allow for even more realistic textures and finishes that mimic natural materials more accurately.

- Color and Pattern Customization: Future developments in pigment and coating technology will offer enhanced color options, allowing for more vibrant and durable finishes. Customization options will also increase, with WPC panels being produced in unique shapes, sizes, and patterns.

Impact on Panel Thickness:

- Custom designs may require specific thicknesses to achieve the desired aesthetic effect. For instance, thicker panels may be used for bold architectural features, while thinner panels may be used for lighter, more modern looks. The flexibility of design will continue to allow for a wide variety of thickness options to meet different aesthetic preferences.

5.6 Global Expansion and Market Diversification

As the global demand for sustainable and durable building materials rises, the market for WPC wall panels will continue to expand into new regions. This will drive innovation as manufacturers cater to different climates, cultural preferences, and regulatory standards across the globe.

Key Developments:

- International Standards: As WPC wall panels become more widely used across different regions, there will be an increased focus on meeting international quality standards, certifications, and regulations. Manufacturers will need to adhere to specific building codes and environmental standards that vary by region.

- Localized Production: To meet the growing demand in various markets, manufacturers may establish production facilities closer to key markets, reducing shipping costs and carbon footprints while also allowing for more tailored products.

Impact on Panel Thickness:

- Regional variations in climate and regulations will influence the preferred thickness of WPC panels in different parts of the world. For example, regions with heavy snowfall or intense sun exposure may require thicker panels for insulation and durability, while tropical or coastal regions may prioritize thinner, moisture-resistant panels.

6.Conclusion

The future of WPC wall panels is bright, with innovations in sustainability, technology, insulation, and design flexibility set to drive further growth in the industry. As climate concerns and energy efficiency continue to dominate the global construction agenda, WPC panels will remain a popular choice for architects, builders, and homeowners. By staying attuned to these emerging trends, manufacturers can continue to evolve their products to meet the changing needs of the market and provide optimal performance, regardless of climate or usage conditions.

As WPC technology advances, the ability to select the right thickness based on climate, environmental factors, and usage conditions will become easier and more precise. Whether for residential, commercial, or industrial applications, WPC panels will remain a durable, versatile, and sustainable choice for building projects in the future.