Table of Contents

ToggleIntroduction

In modern hospitality design, bathrooms are no longer just functional spaces—they are an essential part of the guest experience. Cleanliness, durability, aesthetics, and maintenance efficiency all directly impact hotel brand reputation and operating costs. Among many material options, PVC marble sheet has emerged as one of the most widely adopted solutions for shower wall applications in hotels worldwide.

From luxury resorts to business hotels and modular hospitality projects, procurement managers, architects, and developers are increasingly selecting PVC marble sheets instead of traditional ceramic tiles or natural marble. The reasons are both technical and commercial: waterproof performance, cost efficiency, fast installation, consistent aesthetics, and long service life.

In this article, we will deeply analyze why hotels choose PVC marble sheets for shower wall applications, combining technical performance, real project needs, market trends, and long-term return on investment perspectives.

The Evolution of Hotel Shower Wall Materials

Traditional Materials Used in Hotel Bathrooms

Historically, hotel shower walls relied mainly on:

- Ceramic tiles

- Natural marble or granite

- Glass panels

- Painted waterproof wall systems

Each of these materials has advantages but also significant limitations. For example:

Ceramic tiles require grout, which can become moldy or discolored over time. Natural marble offers luxury appearance but comes with high cost, heavy weight, and complex installation requirements.

Today, hotel developers are moving toward wall panel systems because they offer faster installation, seamless waterproofing, and lower maintenance.

The Rise of Decorative Wall Panel Systems

Modern hotel construction and renovation focus on:

- Shorter construction cycles

- Lower lifecycle cost

- Standardized design across hotel chains

- Higher hygiene standards

Wall panels—including PVC marble sheet—are becoming mainstream in hotel bathroom design because they meet these performance indicators better than traditional tile systems.

PVC marble sheet, in particular, combines the visual luxury of natural stone with the performance advantages of polymer materials.

Superior Waterproof Performance for Wet Environments

Non-Porous Material Structure

PVC marble sheets are manufactured from dense polymer resin, making them inherently non-porous and waterproof. Unlike natural stone or tile systems, they do not absorb moisture or allow water to penetrate through the surface.

Water absorption can be close to zero, which dramatically reduces risks of swelling, cracking, or structural degradation in wet environments.

Mold and Mildew Prevention

In hotel showers, mold prevention is critical for both hygiene and maintenance cost control. PVC marble sheets prevent moisture penetration and eliminate grout lines—two major sources of mold growth in tile installations.

This directly improves:

- Guest satisfaction

- Housekeeping efficiency

- Indoor air quality

Long-Term Moisture Stability

PVC marble sheets maintain structural stability even in high humidity areas such as:

- Shower enclosures

- Spa facilities

- Coastal hotels

- Indoor pool areas

They do not warp, rot, or delaminate like wood-based panels or poorly sealed natural stone.

Significant Cost Advantages for Hotel Projects

Lower Material Cost Compared to Marble

Natural marble is expensive—not only in material cost but also in logistics and installation. PVC marble sheets can reduce total project cost dramatically.

Hotels can save approximately 60–70% compared with natural marble installations while maintaining a similar visual appearance.

Typical price comparison:

- Natural marble: $50–150/m²

- Ceramic tiles: $20–60/m²

- PVC marble sheet: $8–25/m²

Lower Labor and Installation Cost

PVC marble sheets require:

- No grout

- No stone polishing

- No heavy stone cutting

- No wet cement installation

This significantly reduces labor cost and construction complexity.

Better ROI for Hotel Investors

For hotels operating hundreds of rooms, material decisions directly affect profitability. Lower upfront cost plus lower long-term maintenance means better lifecycle ROI.

Fast Installation and Shorter Renovation Cycles

Critical for Hotel Operation Continuity

Hotels often cannot afford long renovation downtime. Wall panel systems can reduce installation time by 40–60% compared with tile installation.

Some projects report installation speeds up to four times faster than marble systems.

Dry Installation Methods

PVC marble sheets can be installed using:

- Adhesive bonding

- Mechanical fixing

- Frame mounting systems

This allows faster renovation, less dust, and less noise—important for hotels renovating while still operating.

Faster Room Turnover

Faster installation means:

- Faster project completion

- Earlier room availability

- Reduced revenue loss during renovation

Lightweight Structure and Structural Safety Benefits

Reduced Building Load

PVC marble sheets weigh roughly 3–4 kg/m², while natural marble can weigh 25–60 kg/m².

This provides huge advantages for:

- High-rise hotels

- Old building renovation

- Modular hotel structures

Easier Transportation and Handling

Lightweight materials reduce shipping cost and installation risk. They also minimize wall stress and structural load concerns.

Aesthetic Flexibility and Brand Design Consistency

Realistic Marble Appearance

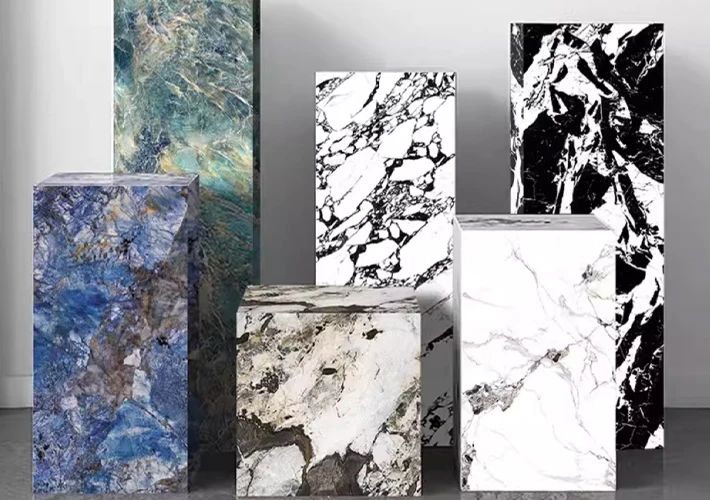

PVC marble sheets can replicate premium stone patterns such as:

- Carrara White

- Calacatta Gold

- Black Galaxy

- Travertine

Hotels can achieve luxury bathroom aesthetics without the cost or installation complexity of natural stone.

Seamless Visual Effect

Unlike tiles, PVC marble sheets can create nearly seamless surfaces. This enhances luxury perception and prevents dirt accumulation in grout lines.

Consistent Color and Pattern

Natural stone has batch variation. PVC marble sheets provide uniform color and pattern, which is crucial for hotel chains standardizing room design across multiple locations.

Low Maintenance and Easy Cleaning for Hotel Operations

Smooth Non-Porous Surface

PVC marble sheets can be cleaned using water or mild cleaners without damaging the surface.

No Grout Maintenance

Tile grout often requires:

- Re-sealing

- Mold cleaning

- Re-grouting over time

PVC marble eliminates this maintenance burden.

Long Service Life

With proper installation, PVC marble sheets can last 15–20 years, offering strong long-term value for hotel investors.

Fire Safety and Compliance with Hotel Standards

Fire safety is mandatory in hospitality buildings. High-quality PVC marble sheets can meet B1 fire-retardant standards and reduce flame spread.

Benefits include:

- Self-extinguishing behavior

- Low smoke emission

- Compliance with commercial building fire codes

These features make PVC marble sheets suitable for hotels, hospitals, and airports.

Global Market Trends Driving Hotel Adoption

Growing Use in Hotel Renovation Projects

PVC marble sheets are widely used in Asia, Europe, and the Middle East, especially in large-scale hotel renovation and new construction projects.

Sustainability and Green Building

PVC marble sheets can be recyclable and require less energy than natural stone mining and processing.

Case Study Insights

Real hotel projects have reported:

- Cost reduction up to 65%

- Installation time reduction up to 40%

- Cleaning time reduction around 30%

Conclusion

PVC marble sheets are becoming a strategic material choice for hotel shower wall applications because they deliver a rare combination of performance, aesthetics, and cost efficiency.

Hotels choose PVC marble sheets because they offer:

- Complete waterproof performance

- Significant cost savings vs natural marble

- Faster installation and reduced downtime

- Lightweight and structurally safe design

- Luxury appearance with consistent quality

- Easy cleaning and low maintenance

- Fire safety compliance

- Strong global market acceptance

As the hospitality industry continues to focus on operational efficiency, hygiene, and design standardization, PVC marble sheets are expected to remain a dominant solution for hotel bathroom wall systems.