Table of Contents

ToggleIntroduction

In the modern interior decoration industry, PVC ceiling panels have emerged as one of the most popular and cost-effective materials for ceilings in commercial and residential projects. They are widely used in hotels, bathrooms, and kitchens due to their waterproof, lightweight, and durable properties. Compared to traditional ceiling materials like gypsum boards or wood, PVC panels offer better resistance to moisture, easier maintenance, and a more affordable price — making them ideal for large-scale construction and renovation projects.

As global demand for decorative materials continues to rise, wholesale PVC ceiling panels from China have become a preferred option for importers, distributors, and contractors worldwide. In this article, we will take a detailed look at the advantages, applications, types, production process, and wholesale opportunities of PVC ceiling panels, helping you make an informed decision for your next project or business.

What Are PVC Ceiling Panels?

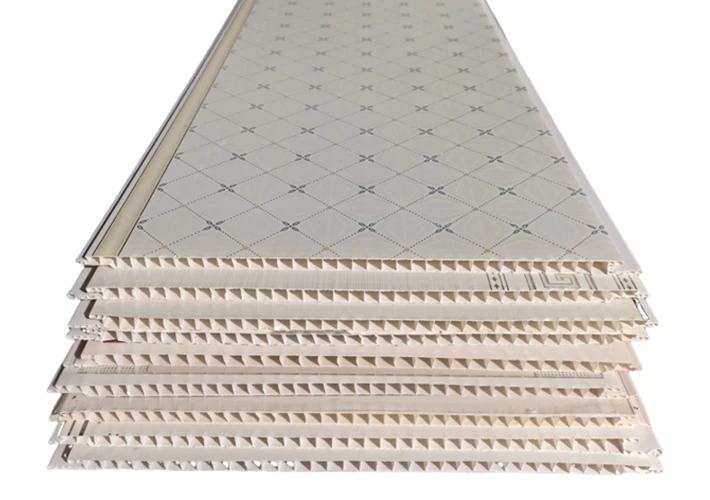

PVC (Polyvinyl Chloride) ceiling panels are decorative boards made from rigid PVC resin, combined with various additives such as stabilizers, lubricants, and colorants. These materials are processed through extrusion, printing, and lamination techniques to create a lightweight and visually appealing ceiling solution.

Unlike conventional plaster or wooden ceilings, PVC panels are waterproof, fire-retardant, and termite-proof, which makes them suitable for humid environments such as kitchens, bathrooms, and basements. Their modular design allows for quick and clean installation without the need for professional tools or messy adhesives.

Key Characteristics:

- Material: 100% PVC or PVC composite

- Surface Finish: Glossy, matte, laminated, or printed with marble, wood, or metallic effects

- Dimensions: Common sizes include 200mm × 3000mm, 250mm × 6000mm, and customized lengths

- Thickness: Usually between 5mm to 12mm

- Installation Method: Tongue-and-groove interlocking system

Advantages of Using PVC Ceiling Panels

When compared with other ceiling materials, PVC ceiling panels offer numerous functional and economic advantages. Below are the key reasons why these panels have gained popularity in both residential and commercial interiors:

2.1 Waterproof and Moisture Resistant

PVC panels are made from non-porous material, preventing the absorption of moisture. This makes them ideal for high-humidity areas like bathrooms, kitchens, and laundry rooms. Unlike gypsum or wooden ceilings, PVC panels do not swell, rot, or warp.

2.2 Lightweight and Easy Installation

One of the main advantages of PVC ceiling panels is their lightweight structure. They can be easily transported, cut, and installed with minimal labor. The tongue-and-groove system allows for fast interlocking, reducing installation time significantly.

2.3 Fire Retardant and Safe

High-quality PVC panels contain fire-retardant additives, making them self-extinguishing when exposed to flame. This enhances safety in commercial buildings like hotels or restaurants.

2.4 Cost-Effective

PVC ceiling panels are affordable compared to gypsum boards or aluminum ceilings. Their long service life and low maintenance costs further contribute to overall savings, especially for large-scale projects.

2.5 Aesthetic Variety

PVC panels are available in a wide range of colors, textures, and finishes — from marble and wood grain to metallic and matte designs. This allows architects and designers to create visually appealing interiors while maintaining functionality.

2.6 Termite and Corrosion Resistance

PVC material is inorganic and corrosion-resistant, ensuring long-term durability. It’s not affected by insects, termites, or rust, which is a common problem with metal-based ceiling systems.

2.7 Low Maintenance

Cleaning PVC panels requires only a damp cloth or mild detergent. The smooth surface prevents dust and stains from adhering, maintaining a clean and polished look for years.

Applications of PVC Ceiling Panels

PVC ceiling panels are highly versatile and adaptable for various indoor applications. Let’s explore their usage in different environments:

3.1 Hotels

Hotels require a balance between luxury aesthetics and practical functionality. PVC ceiling panels meet both needs by offering:

- Decorative finishes that mimic marble or wood

- Easy cleaning and moisture resistance for bathrooms and spas

- Fire-retardant properties for safety compliance

They are commonly used in hotel lobbies, guest bathrooms, corridors, restaurants, and even conference rooms, providing an elegant and durable solution.

3.2 Bathrooms

Bathrooms are the most common area where PVC ceiling panels are applied. Since they are 100% waterproof and anti-mold, they prevent issues like peeling paint, humidity stains, or corrosion.

They can also be combined with LED lights or ventilation systems, creating a modern, functional, and stylish ceiling.

3.3 Kitchens

In kitchens, moisture, heat, and grease are constant challenges. PVC ceiling panels offer excellent resistance to steam and heat, and their non-stick surface makes cleaning effortless. For restaurant or commercial kitchens, PVC ceilings are a practical choice to maintain hygiene standards.

3.4 Office Buildings and Retail Shops

For commercial interiors, PVC panels provide a cost-effective alternative to aluminum ceilings. Their clean, modern appearance suits offices, shops, and showrooms.

3.5 Residential Interiors

Apart from kitchens and bathrooms, PVC panels are also used in living rooms, bedrooms, and balconies, especially in budget-friendly housing or renovation projects.

Types of PVC Ceiling Panels

Different projects require different surface effects and structural features. Here are the most common types available on the market:

4.1 Printed PVC Ceiling Panels

These panels have designs printed directly onto the surface, including marble, wood, or floral patterns, using UV printing technology. They are ideal for hotels and residential interiors that demand aesthetic appeal.

4.2 Laminated PVC Ceiling Panels

Laminated panels come with an additional protective film for extra durability and shine. They are scratch-resistant, easy to clean, and suitable for humid environments like bathrooms and kitchens.

4.3 Glossy PVC Ceiling Panels

Glossy panels create a bright and reflective ceiling effect, often used in commercial spaces or modern home designs.

4.4 Matte PVC Ceiling Panels

Matte panels offer a soft, elegant appearance, ideal for bedrooms, offices, and hotel corridors.

4.5 Hollow PVC Ceiling Panels

Hollow structure panels are lightweight and cost-effective, suitable for suspended ceilings and false ceiling systems.

The Production Process of PVC Ceiling Panels

To ensure quality and consistency, PVC ceiling panels go through a series of strict manufacturing steps. Here’s an overview of the production process:

- Raw Material Preparation:

PVC resin, stabilizers, and other additives are mixed to form a uniform compound. - Extrusion:

The mixture is melted and extruded through a die to create continuous sheets of desired dimensions. - Surface Treatment:

The surface is printed, laminated, or coated with protective layers depending on the design. - Cutting and Shaping:

Panels are cut into specific lengths and their edges are shaped into interlocking tongues and grooves. - Quality Inspection:

Every batch undergoes strict inspection for thickness, color consistency, and surface defects. - Packaging:

Finished panels are packed in protective wrapping and stacked for export.

Why Import PVC Ceiling Panels from China?

China is the largest producer and exporter of PVC decorative materials in the world. Buying PVC ceiling panels wholesale from a reliable Chinese manufacturer offers several competitive advantages:

6.1 Cost Advantage

Due to large-scale production and mature industrial chains, Chinese manufacturers offer lower prices without compromising quality.

6.2 High Quality and Customization

Modern Chinese factories utilize advanced extrusion equipment, UV printing technology, and strict quality control systems, ensuring stable product quality. OEM and ODM customization services are also widely available.

6.3 Fast Delivery and Global Supply Chain

Chinese suppliers have efficient logistics networks that support global exports, ensuring timely delivery for bulk orders.

6.4 Wide Range of Styles

From simple white panels to luxurious marble finishes, Chinese factories provide a diverse selection of patterns and colors to meet various market preferences.

How to Choose the Right PVC Ceiling Panel Supplier

If you plan to purchase PVC ceiling panels wholesale, choosing the right supplier is crucial. Consider the following factors:

Factory Certification:

Look for ISO-certified factories with a proven export record.

Material Quality:

Ensure that panels are made from 100% virgin PVC, not recycled material.

Design and Customization:

Ask if the supplier offers custom printing or lamination options.

Sample Testing:

Request samples to evaluate surface quality, thickness, and color accuracy.

After-Sales Support:

Reliable suppliers provide technical support, installation guides, and warranty services.

Global Market Outlook for PVC Ceiling Panels

The global market for PVC ceiling panels has shown steady growth in recent years due to rising demand for affordable and waterproof decorative materials. According to recent industry data:

- The global PVC ceiling panel market is projected to reach USD 4.2 billion by 2030, growing at a CAGR of 5.6%.

- The Asia-Pacific region (especially China and India) remains the largest production base.

- North America and Europe show increasing demand for eco-friendly and low-maintenance ceiling solutions in both residential and commercial sectors.

As sustainability becomes a global priority, many factories now produce lead-free and recyclable PVC panels, aligning with environmental regulations.

Conclusion

PVC ceiling panels offer an excellent balance of functionality, aesthetics, and affordability, making them the ideal solution for hotels, bathrooms, kitchens, and commercial interiors. Their waterproof, fire-resistant, and low-maintenance nature ensures long-lasting performance even in challenging environments.

For importers, wholesalers, and project contractors, sourcing wholesale PVC ceiling panels from China can significantly reduce costs while maintaining high-quality standards. With a wide variety of styles, quick installation, and superior durability, PVC ceiling panels continue to be a top choice in the global decorative materials market.

If you are looking for a reliable PVC ceiling panel manufacturer and supplier in China, we offer factory-direct wholesale services, customized design options, and professional export support for your project needs.

Contact us today to get the latest catalog and quotation for your upcoming hotel, bathroom, or kitchen decoration project.