As the international demand for eco-friendly and durable decorative materials continues to rise, WPC wall panels (Wood Plastic Composite wall panels) have become one of the most popular interior and exterior wall finishing solutions. Their waterproof performance, long service life, and modern wood-grain aesthetics make them highly attractive to global distributors, contractors, and project developers.

China is the largest production base for WPC products, offering a wide range of designs, competitive prices, and strong export capacity. However, importing from China requires careful planning and professional knowledge. Many importers encounter problems such as inconsistent quality, long delivery times, hidden logistics costs, and certification issues simply because they did not prepare adequately.

Table of Contents

ToggleUnderstand WPC Wall Panel Specifications Before Importing

Before sourcing from China, you must clearly understand what WPC wall panels are, the types available, and how specifications affect both quality and price.

1.1 What WPC Wall Panels Are Made Of

WPC is a composite of:

- Wood or bamboo fibers (30–60%)

- High-density polyethylene (HDPE) or polymer resin

- Calcium powder and stabilizers

- Additives such as flame retardants, UV inhibitors, and colorants

Different factories use different formulas, so stability and durability vary widely.

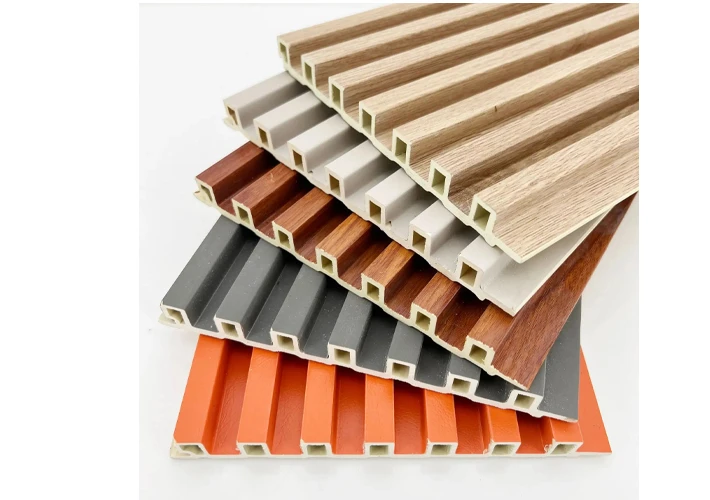

1.2 Types of WPC Wall Panels in China

China offers multiple styles:

- Standard interior flat WPC panels (common for wall cladding)

- Fluted / slatted decorative WPC panels

- 3D embossed WPC panels

- Co-extruded WPC panels (higher protection layer)

- Exterior WPC cladding panels

- WPC ceilings and mouldings

Each type targets different markets and price segments.

1.3 Key Technical Specifications to Confirm

Before placing an order, always confirm:

- Panel width (150–300mm common)

- Thickness (8mm–25mm)

- Length (2.8m, 3m, 3.2m, 4m, 5.9m)

- Density level

- Surface film type (PVC film / hot stamping / ASA co-extrusion)

- Gloss level and texture

- Color code

- Fire rating (e.g., ASTM E84 / EN13501-1)

- Indoor vs. outdoor application

You should also confirm raw material ratio, because lower-grade factories may reduce HDPE or use weaker recycled plastics.

1.4 Quality Grades in the Market

Chinese factories generally supply 3 quality levels:

- Grade A – best formula, stable performance, suitable for EU/US markets

- Grade B – middle quality, widely used in Southeast Asia & Africa

- Grade C – budget option; higher risks of deformation or fading

Choosing the correct grade avoids after-sale problems.

Evaluate Supplier Qualifications and Factory Capabilities

Selecting the right factory is the most critical step. China has hundreds of WPC producers, but quality varies drastically.

2.1 Check if the Supplier is a Real Manufacturer

A real WPC wall panel factory should have:

- Multiple extrusion production lines

- Raw material mixing equipment

- Lamination/film covering workshop

- CNC cutting machines

- Packing machines

- QC laboratory

Trading companies may offer lower prices but often have inconsistent quality.

2.2 Examine Factory Scale and Export Experience

A reliable WPC supplier usually:

- Has at least 5 years of export experience

- Supplies 30–200 containers per month

- Understands fire rating and VOC requirements of different countries

- Provides references from distributors or project contractors

Factories with poor export experience often lack proper documentation.

2.3 Check Certificates and Compliance

Common export-related certifications include:

- CE certification

- ISO9001 & ISO14001

- SGS / TÜV test reports

- Fire rating (ASTM E84 / EN13501-1)

- VOC / formaldehyde emission test reports

If you import into Europe, Middle East, or the United States, these certificates may be mandatory.

2.4 Do a Factory Audit or Third-Party Inspection

When dealing with long-term import projects:

- Visit the factory yourself

- OR hire SGS / TUV / Intertek for factory audit

This eliminates the risk of working with non-professional suppliers.

Control Product Quality Through Sampling and Inspections

WPC wall panel quality varies widely depending on material ratio, equipment, and QC management. To prevent receiving poor-quality goods, you must implement strict quality control measures.

3.1 Sample Confirmation Before Mass Production

Request samples that represent exact mass production specifications, including:

- Color

- Thickness

- Surface hardness

- Scratch resistance

- Film quality

- Density

Do not approve production until samples fully match your expectations.

3.2 Mid-Production QC (Recommended for Large Orders)

Check:

- Panel thickness tolerance

- Density uniformity

- Color consistency

- Surface condition (scratches, bubbles)

- Packaging materials

Mid-production QC prevents large-scale defects.

3.3 Final Pre-Shipment Inspection

Before shipment, ensure:

- Correct quantity

- No color difference between batches

- Proper packaging strength

- Accurate labeling

- Moisture-proof and scratch-proof wrapping

If you work with a new supplier, final inspection is essential.

3.4 Common Quality Issues to Avoid

Importers often encounter:

- Warping or bending

- Surface film peeling

- Uneven color or fading

- Hollow sound caused by low material density

- Poor lamination adhesion

- Weak fire rating performance

These issues mostly occur with low-end suppliers or when buyers choose unrealistically low prices.

Understand Pricing Structure and Hidden Costs in WPC Imports

Price differences between Chinese WPC manufacturers can exceed 40%. Before comparing prices, understand what determines the cost.

4.1 Key Factors Affecting WPC Prices

- Raw material quality (virgin vs. recycled HDPE)

- Film type and brand

- Co-extrusion or non-co-extrusion

- Panel thickness and density

- Fire retardant additives

- Packaging requirements

- Order size

The cheapest suppliers often compromise on material mix.

4.2 Typical Factory Prices (Reference)

- Standard interior WPC panels: $3.5–6.5 per piece

- Slatted WPC wall panels: $12–16 per m²

- Exterior cladding: $16–26 per m²

- Co-extruded panels: 20–30% higher

Actual prices fluctuate depending on raw material costs.

4.3 Hidden Import Costs You Must Calculate

- Local customs duty

- VAT / GST

- Port handling fees

- Inland transportation

- Container inspection fees

- Ship delay surcharges

- Currency exchange fluctuations

Always calculate the landed cost, not only FOB price.

4.4 Choose Value, Not the Lowest Price

Low-cost WPC panels often lead to:

- Shorter lifespan

- Complaints from end customers

- Warranty issues

- Higher replacement costs

A stable supplier is more important than the lowest quote.

Plan Shipping, Logistics, and Documentation Properly

Logistics is a major part of WPC importation. Poor planning may lead to delays or extra costs.

5.1 Choose the Correct Incoterms

Most importers choose:

- FOB – Recommended

- CIF – Supplier arranges shipping

- DDP – Door-to-door but higher risk

Avoid EXW unless you are experienced.

5.2 Container Loading Requirements

WPC panels are long products. Recommended containers:

- 20GP: 28–30 CBM

- 40GP: 58–60 CBM

- 40HQ: 68–72 CBM (best option)

Fluted panels are typically shipped in 40HQ.

5.3 Shipping Time Estimates

- Southeast Asia: 7–12 days

- Middle East: 15–22 days

- Europe: 25–35 days

- USA: 18–28 days

- South America: 35–50 days

5.4 Required Customs Documents

Your supplier must provide:

- Commercial invoice

- Packing list

- Bill of lading

- Certificate of origin (FORM E / RCEP / etc.)

- HS code: 392590

- Insurance document (if CIF)

Missing paperwork may cause delays.

5.5 Ensure Loading Supervision

During container loading, verify:

- Panels are packed tightly

- Waterproof wrapping is applied

- Labels match the packing list

- Cartons are not damaged

For large orders, hire a third-party inspector.

Avoid Common Pitfalls and Build Long-Term Cooperation

Many importers make avoidable mistakes when buying WPC wall panels from China.

6.1 Do Not Rely on Photos Only

Always request:

- Samples

- Testing reports

- Videos of production

Photos alone cannot represent real product quality.

6.2 Avoid Suppliers With Extremely Low Prices

If the price is far below market average, the supplier may be:

- Using recycled plastics

- Cutting material ratio

- Reducing panel density

- Using cheap film

- Offering inconsistent quality

Choose suppliers that offer stable quality and transparent production processes.

6.3 Start With a Trial Order

Recommended process:

Sample confirmation

Small trial order

Bulk order after quality verification

6.4 Build Long-Term Collaboration

Long-term relationships give you:

- Better pricing

- Priority production

- Free design and branding support

- Stable color matching

- Faster problem resolution

Reliable suppliers are always willing to provide long-term support.

Conclusion

Importing WPC wall panels from China can be highly profitable, but only if you manage supplier selection, product quality, logistics, and pricing wisely. By understanding specifications, verifying factory capabilities, controlling product quality, planning logistics, and avoiding common pitfalls, you can ensure a smooth and reliable import process.

Looking for a Reliable WPC Wall Panel Manufacturer in China?

We offer:

- High-quality WPC wall panels

- Slatted / fluted wall panels

- Co-extruded panels

- Exterior WPC cladding

- OEM/ODM service

- Fast delivery & strict QC

- Competitive factory prices

📦 Free Samples | 🌍 Global Shipping

📞 Contact us on WhatsApp to get a catalog & quotation