As global interior decoration projects continue to pursue cost control, durability, fast installation, and visual consistency, UV marble sheets have become one of the most widely used decorative wall materials in international markets.

From hotels and apartments to shopping malls, office buildings, and residential projects, UV marble sheets are increasingly replacing natural marble, ceramic tiles, and traditional wall panels.

Among all inquiries from overseas buyers, importers, and contractors, one question appears most frequently:

What is the actual lifespan of UV marble sheets?

This article provides a comprehensive, professional, and project-oriented analysis of the lifespan of UV marble sheets. Instead of giving a simple number, we will explain why UV marble sheets last as long as they do, what factors affect their service life, and how buyers can maximize durability in real projects.

As a professional UV marble sheet manufacturer and exporter in China, the following analysis is based on production standards, material testing, and long-term feedback from global projects.

Table of Contents

ToggleWhat Is the Average Lifespan of UV Marble Sheets?

Under normal indoor usage conditions, high-quality UV marble sheets typically have a service life of 15 to 25 years.

In many commercial and residential projects with proper installation and maintenance, the actual lifespan can even exceed 25 years without structural failure or serious surface degradation.

Typical Lifespan by Application Scenario

Different usage environments directly affect product longevity. Based on export project data, UV marble sheets generally perform as follows:

- Residential interiors (living rooms, bedrooms, corridors):

- 20–25 years

- Hotels, serviced apartments, and hospitality projects:

- 15–20 years

- Commercial offices and public buildings:

- 15–20 years

- Retail spaces, restaurants, and shopping malls:

- 12–18 years

These figures assume the use of export-grade UV marble sheets, not low-cost domestic-grade products.

Why UV Marble Sheets Have a Predictable Lifespan

Unlike natural stone, whose quality varies widely, UV marble sheets are industrial products with controlled formulations and standardized processes. This allows manufacturers to design panels with predictable aging behavior, which is especially important for large-scale projects and long-term maintenance planning.

Material Composition and Structure: The Foundation of Long Lifespan

The lifespan of UV marble sheets starts with their internal structure. Understanding this structure explains why they outperform many traditional decorative materials.

PVC-Based Core Material

The core layer is typically made of high-density PVC composite, often combined with calcium carbonate. This structure offers:

- Excellent dimensional stability

- Strong resistance to moisture and humidity

- No swelling, rotting, or corrosion

Compared with MDF or gypsum-based boards, PVC cores remain stable even after years of use in humid environments.

Decorative Film Layer

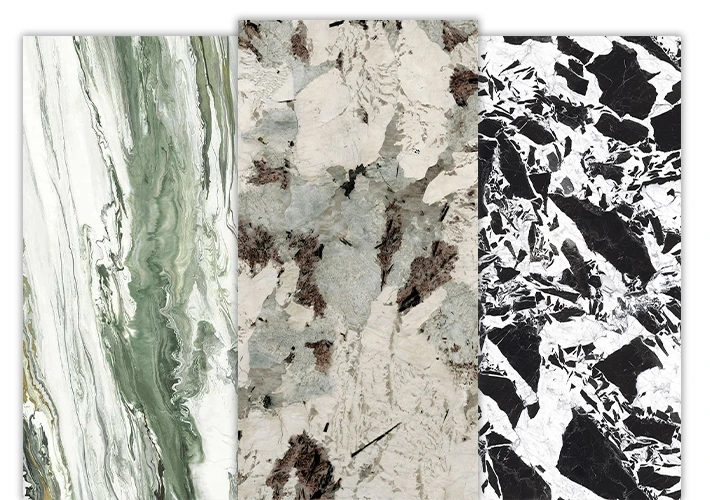

The decorative layer uses high-resolution printed film that accurately reproduces marble veins, stone textures, and luxury finishes.

High-quality film ensures:

- Color consistency

- Clear pattern definition

- Long-term adhesion to the base board

Low-grade films may fade or delaminate earlier, directly shortening lifespan.

UV Coating Layer

The surface UV coating is the most critical factor affecting durability. Multiple layers of UV lacquer are cured under ultraviolet light, forming a hardened protective surface.

This coating:

- Protects against scratches and abrasion

- Seals the decorative film

- Improves chemical and stain resistance

Without proper UV coating thickness and curing, the lifespan of UV marble sheets can be reduced by 30–40%.

UV Coating Performance and Surface Durability Over Time

The reason UV marble sheets last significantly longer than ordinary PVC panels lies primarily in their UV-coated surface system.

UV Coating Thickness and Layers

Export-grade UV marble sheets usually have:

- 3–5 layers of UV coating as standard

- 6–8 layers for premium commercial applications

Thicker coatings provide:

- Higher surface hardness

- Better scratch resistance

- Longer gloss retention

This directly impacts how the sheet looks after 5, 10, or even 15 years of use.

Scratch Resistance and Daily Wear

In real projects, wall panels are exposed to:

- Furniture movement

- Cleaning tools

- Human contact

High-quality UV marble sheets typically reach 2H–4H surface hardness, allowing them to withstand daily wear without visible damage.

In hotels and office corridors, properly specified UV marble sheets often show minimal surface wear even after 8–10 years.

Stain and Chemical Resistance

UV coatings also protect against:

- Cleaning agents

- Mild acids and alkalis

- Common household stains

This prevents surface penetration and discoloration, preserving appearance over long periods.

Environmental Resistance: Moisture, Heat, and Light Exposure

Environmental conditions play a decisive role in determining how long UV marble sheets last in real-world applications.

Moisture and Humidity Resistance

One of the biggest advantages of UV marble sheets is their excellent resistance to moisture.

Because PVC does not absorb water:

- No swelling

- No warping

- No mold growth

This makes UV marble sheets particularly suitable for:

- Bathrooms

- Kitchens

- Coastal areas

- High-humidity regions

In these environments, UV marble sheets can maintain structural stability for 15–20+ years, while traditional materials may fail much earlier.

Temperature Stability

UV marble sheets are designed for indoor temperature ranges typically found in residential and commercial buildings.

They remain stable under:

- Air-conditioned environments

- Normal heating systems

Extreme temperature fluctuations should be avoided, but under standard indoor conditions, temperature has minimal impact on lifespan.

Light and UV Exposure

Despite the name, UV marble sheets are not designed for long-term outdoor exposure.

- Under normal indoor lighting, color stability remains high for 10–15 years

- In areas with strong direct sunlight, gradual fading may occur after long-term exposure

Using curtains, blinds, or UV-protective glass can significantly extend color life.

Installation Quality and Maintenance: Hidden Factors That Extend Lifespan

Even premium UV marble sheets cannot reach their full lifespan without correct installation and reasonable maintenance.

Importance of Proper Installation

Correct installation ensures:

- Even stress distribution

- Secure panel fixation

- Prevention of panel movement and cracking

Common installation methods include:

- Structural adhesive bonding

- Aluminum profile systems

- Combined mechanical fixing

Poor installation is one of the main reasons for premature failure reported in low-quality projects.

Maintenance Requirements

UV marble sheets are considered low-maintenance materials, especially compared to natural stone.

Recommended practices:

- Use soft cloths or sponges

- Avoid abrasive cleaners

- Clean regularly to prevent buildup

With basic maintenance, surface gloss and appearance can be preserved for many years.

Maintenance Impact on Lifespan

Projects with regular cleaning and correct usage often exceed their expected lifespan by 5–8 years, especially in hospitality and commercial environments.

Comparison With Other Decorative Materials: Lifespan and Cost Performance

To properly evaluate the lifespan of UV marble sheets, it is useful to compare them with alternative materials commonly used in interior decoration.

UV Marble Sheets vs Natural Marble

Natural marble can last longer structurally, but:

- Requires sealing and polishing

- Is sensitive to moisture and stains

- Has high maintenance costs

UV marble sheets offer a more stable and predictable lifespan with significantly lower lifecycle costs.

UV Marble Sheets vs Ordinary PVC Marble Sheets

Compared to non-UV PVC marble sheets:

- UV versions last 30–50% longer

- Better scratch resistance

- Superior gloss retention

This makes UV marble sheets more suitable for commercial and high-traffic projects.

UV Marble Sheets vs Acrylic Panels

Acrylic panels provide high gloss but:

- Scratch easily

- Yellow over time

UV marble sheets balance durability, aesthetics, and cost, making them more suitable for long-term projects.

How Buyers Can Ensure Maximum Lifespan in Real Projects

For importers, wholesalers, and project buyers, the lifespan of UV marble sheets begins with supplier selection.

What to Check Before Purchasing

- UV coating thickness and hardness

- Raw material formulation

- Quality certifications and test reports

- Sample aging and scratch tests

Choosing a factory with stable production standards is critical for long-term performance.

Why Factory Experience Matters

As an experienced UV marble sheet manufacturer in China, we understand:

- How to balance cost and durability

- How to control raw material consistency

- How to supply stable quality for large-scale projects

This is especially important for hotels, apartments, and commercial developments where replacement costs are high.

Conclusion: What Is the Lifespan of UV Marble Sheets?

In summary:

- Average lifespan: 15–25 years

- Key influencing factors: material quality, UV coating, environment, installation, maintenance

- Best application: indoor residential and commercial wall decoration

- Cost-performance: excellent compared with natural stone and traditional panels

When produced to export standards, installed correctly, and used in appropriate environments, UV marble sheets offer long-lasting performance with predictable durability, making them an ideal choice for global decoration projects.

Looking for Long-Life UV Marble Sheets for Wholesale or Projects?

We are a professional UV marble sheet manufacturer and exporter in China, offering:

- Stable export-grade quality

- Custom sizes, thicknesses, and designs

- Project-oriented technical support

- Long-term supply for wholesalers and contractors

If you are seeking UV marble sheets with proven lifespan performance, feel free to contact us for samples and specifications.