Table of Contents

ToggleUV sheets

UV PVC Marble Sheet For Wall 3D Print

PVC marble sheet captures the exquisite beauty of natural marble with remarkable precision. From the intricate veining and rich textures to the captivating color variations, these sheets emulate the sophistication and opulence of genuine marble, adding a touch of luxury to any interior space.

View MoreUV marble sheets are a type of decorative material used in interior design and construction. Here are some key features and characteristics of UV marble sheets:

- Composition: UV marble sheets typically consist of a base material such as MDF (Medium Density Fiberboard) or HDF (High Density Fiberboard) that is coated with a layer of PVC (Polyvinyl Chloride) film. The PVC film is printed with a high-resolution image of marble patterns and colors, providing a realistic and elegant appearance.

- UV Curing: The top layer of UV marble sheets undergoes a UV curing process, which involves exposure to ultraviolet light to harden and cure the surface. This UV curing process enhances the durability and scratch resistance of the sheets, making them suitable for high-traffic areas and environments prone to wear and tear.

- Appearance: UV marble sheets are designed to mimic the natural beauty of marble, offering a wide range of patterns, colors, and veining to replicate different types of marble. They provide a luxurious and sophisticated aesthetic similar to real marble but at a more affordable price point.

- Durability: UV marble sheets are known for their durability and resistance to scratches, stains, moisture, and fading. The UV-cured top layer adds an extra level of protection, making the sheets long-lasting and easy to maintain. They are suitable for various interior applications, including wall paneling, furniture surfaces, countertops, and decorative accents.

- Installation: UV marble sheets are relatively easy to install and can be cut, drilled, and shaped to fit specific design requirements. They can be mounted directly onto substrates such as walls, plywood, or MDF using adhesive or mechanical fasteners.

- Maintenance: UV marble sheets require minimal maintenance and can be cleaned with mild soap and water. Avoid using abrasive cleaners or harsh chemicals that may damage the surface finish. With proper care, UV marble sheets can maintain their appearance and integrity for many years.

Overall, UV marble sheets offer a cost-effective alternative to natural marble, providing the timeless beauty and elegance of marble with added durability and practicality for interior design projects.

PVC marble sheets

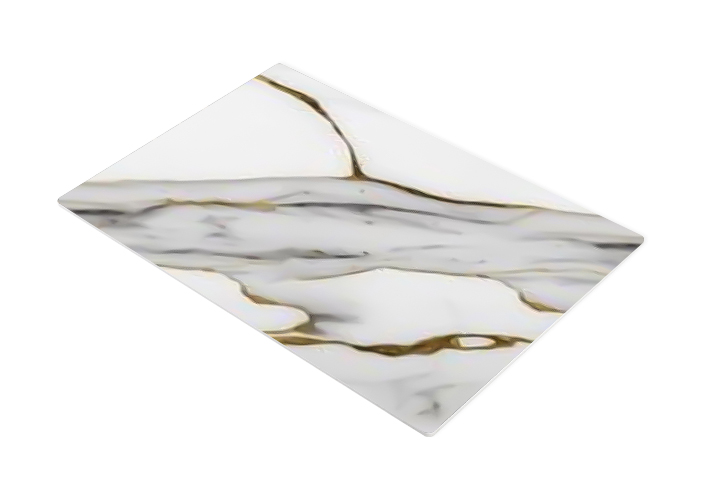

PVC Marble Sheet Gilded Marble Sheet White

PVC marble sheet captures the exquisite beauty of natural marble with remarkable precision. From the intricate veining and rich textures to the captivating color variations, these sheets emulate the sophistication and opulence of genuine marble, adding a touch of luxury to any interior space.

View MorePVC (Polyvinyl Chloride) sheets are versatile materials used in various applications in construction, manufacturing, signage, and interior design. Here are some key features and characteristics of PVC sheets:

- Composition: PVC sheets are made from polyvinyl chloride resin, a synthetic plastic polymer. They may contain additives such as plasticizers, stabilizers, and pigments to enhance specific properties or achieve desired colors and textures. PVC sheets can be manufactured in different forms, including rigid PVC sheets and flexible PVC sheets.

- Versatility: PVC sheets come in a wide range of thicknesses, colors, textures, and finishes, offering versatility in design options. They can be produced with smooth surfaces, embossed textures, or matte/glossy finishes to suit various applications and aesthetic preferences.

- Durability: PVC sheets are known for their durability and resistance to moisture, chemicals, abrasion, and impact. They are inherently weatherproof and can withstand harsh environmental conditions, making them suitable for both indoor and outdoor use. PVC sheets also have excellent electrical insulation properties, making them ideal for electrical enclosures and insulation applications.

- Lightweight: PVC sheets are lightweight compared to many other building materials, which makes them easy to handle, transport, and install. Their lightweight nature does not compromise their strength or durability, making them an attractive option for a wide range of applications.

- Cost-effectiveness: PVC sheets are cost-effective compared to many alternative materials such as metal, wood, or glass. They offer a balance of performance, durability, and affordability, making them a popular choice for various construction and fabrication projects.

- Easy to work with: PVC sheets are easy to cut, shape, drill, and fabricate using standard tools and equipment. They can be thermoformed or molded into different shapes and profiles to meet specific design requirements. PVC sheets can also be welded or bonded together using adhesives or solvents for seamless joints and assemblies.

- Applications: PVC sheets have numerous applications across industries, including but not limited to:

- Construction: Wall cladding, roofing, flooring, ceiling panels, window and door frames, pipes, and fittings.

- Manufacturing: Fabrication of signs, displays, point-of-sale materials, packaging, and industrial components.

- Interior Design: Decorative wall panels, partitions, furniture components, cabinetry, and decorative accents.

In summary, PVC sheets offer a combination of versatility, durability, cost-effectiveness, and ease of installation, making them a popular choice for a wide range of applications in construction, manufacturing, and interior design.

UV marble sheets and PVC sheets are both materials commonly used in interior design and construction, but they have some differences in terms of composition, appearance, and application:

Composition:

- UV Marble Sheet: UV marble sheets are typically made of a base material such as MDF (Medium Density Fiberboard) or HDF (High Density Fiberboard) which is coated with a layer of PVC film that mimics the appearance of marble. The UV curing process is used to harden and cure the top layer, providing durability and a glossy finish.

- PVC Sheet: PVC sheets are made entirely of polyvinyl chloride (PVC) resin. They may come in various forms such as rigid PVC sheets or flexible PVC sheets. These sheets can be solid colored or have various textures and patterns embossed onto the surface.

Appearance:

- UV Marble Sheet: UV marble sheets are designed to resemble natural marble with intricate patterns, veining, and colors. They offer a luxurious and elegant aesthetic similar to real marble but at a more affordable price.

- PVC Sheet: PVC sheets come in a wide range of colors, patterns, and textures, offering versatility in design options. They can mimic various materials such as wood, stone, fabric, or metal, depending on the desired look.

Durability and Maintenance:

- UV Marble Sheet: UV marble sheets are known for their durability and resistance to scratches, stains, and moisture. The UV-cured top layer provides protection against fading and discoloration over time. They are relatively easy to clean with mild soap and water.

- PVC Sheet: PVC sheets are also durable and resistant to moisture, chemicals, and impact. They are easy to maintain and clean with soap and water. However, they may not be as resistant to scratches and abrasion as UV marble sheets.

Application:

- UV Marble Sheet: UV marble sheets are commonly used in interior applications such as wall paneling, furniture surfaces, kitchen countertops, and decorative accents where the look of real marble is desired without the high cost and maintenance.

- PVC Sheet: PVC sheets have a wide range of applications including wall cladding, ceiling panels, flooring, signage, and other decorative elements in both residential and commercial spaces.

In summary, while both UV marble sheets and PVC sheets are versatile materials suitable for interior design, UV marble sheets offer the aesthetic of natural marble with enhanced durability and UV resistance, whereas PVC sheets provide a broader range of design options at a lower cost. The choice between the two depends on specific project requirements, budget, and desired aesthetic.