PU stone panels—also called polyurethane stone panels, PU faux stone panels, or PU decorative wall cladding—have become one of the most popular lightweight wall materials in today’s global building and decoration industry. They offer the realistic appearance of natural stone while greatly reducing weight, installation cost, and transportation risks. As demand grows across North America, Europe, the Middle East, Southeast Asia, and Africa, more buyers want to understand one key topic:

What exactly is PU stone panel made of?

This article provides a complete and professional explanation of PU stone panel materials, production structure, material properties, and why these components together create a durable yet lightweight decorative product. Designed for importers, wholesalers, architects, and project contractors, this guide helps you fully understand PU stone materials before buying from China.

Table of Contents

ToggleOverview: What Is PU Stone Panel?

PU stone panel is a synthetic decorative wall panel manufactured from polyurethane (PU) foam, surface UV coating, and high-definition stone texture film. It mimics the natural appearance of stone, slate, brick, or marble while offering:

- Light weight

- Strong durability

- Thermal insulation

- Waterproof and fire-retardant properties

- Easy installation

- Low transportation cost

Unlike natural stone, PU stone panels do not require mining, cutting, or heavy cement mortar. This makes them a preferred eco-friendly alternative in both interior and exterior decoration.

Many construction companies choose PU stone panels for hotel projects, house facades, garden walls, prefabricated buildings, modular homes, RV interiors, shops, and restaurants.

To understand its performance, let’s break down the material composition.

Main Components of PU Stone Panels

PU stone panels are made of three key layers:

High-density PU (polyurethane) foam core

High-definition stone texture film or sprayed surface

Protective UV coating / anti-scratch layer

Below is a deep explanation of each material.

2.1 Polyurethane Foam (PU Core Material)

What is PU?

Polyurethane is a polymer created by reacting polyol and isocyanate with added blowing agents. PU foam can be rigid or flexible depending on the formulation. For stone panels, manufacturers use high-density rigid PU foam.

Why PU Foam Is Used in Stone Panels

PU foam offers several unique advantages:

- Lightweight: Density ranges between 35–55 kg/m³, nearly 10–20 times lighter than natural stone.

- Strong thermal insulation: Excellent insulation values of 0.024–0.030 W/(m·K).

- Waterproof: PU has a closed-cell structure that blocks water absorption.

- Anti-corrosion: Resistant to moisture, fungi, and insects.

- Shock absorption: Protects walls from impact.

- Long service life: 10–20 years when used outdoors.

Chemical Composition

The PU core typically consists of:

- Polyols

- Isocyanates (MDI)

- Foaming agents

- Flame retardants

- Stabilizers

- Catalysts

This formulation is injected into molds where it expands to form a 3D stone texture.

2.2 Stone Texture Surface Layer

The second layer gives the PU panel the realistic stone appearance.

There are two main technologies:

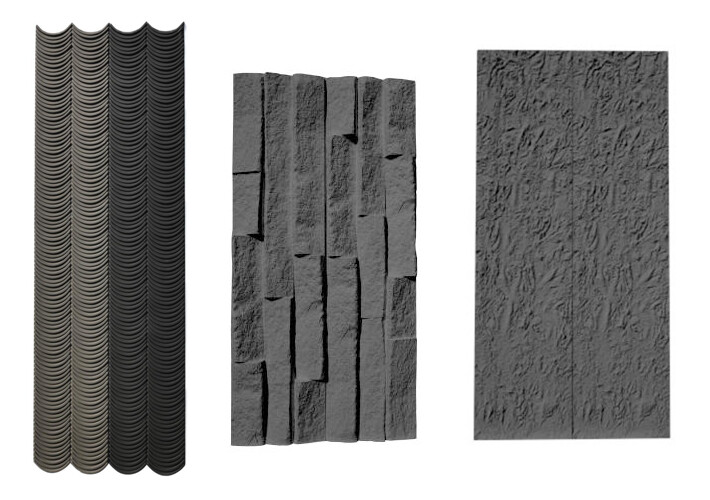

(1) HD Stone Texture Film (Transfer Film)

This method uses high-definition printed PVC film that transfers realistic stone patterns onto the panel. Patterns can replicate:

- Granite

- Marble

- Slate

- Limestone

- Travertine

- Brick

- Cement stone

Film thickness is usually 0.15–0.25 mm, providing excellent detailing and color accuracy.

(2) Sprayed Stone Texture (Handcrafted)

Some manufacturers spray multi-layer coatings directly onto the PU foam:

- Base color

- Stone texture particles

- Gradient tones

- Protective sealing

This technique creates a more natural, rough texture similar to real stone.

Benefits of the Surface Layer

- Ultra-realistic appearance

- UV resistance

- Anti-yellowing

- Scratch resistance

- Customizable textures and colors

2.3 UV Protective Coating (Outer Surface Layer)

The final layer is a transparent UV coating that protects the surface from environmental damage.

Key Functions

- Prevent fading and yellowing under sunlight

- Improve scratch and abrasion resistance

- Enhance anti-stain performance

- Extend outdoor lifespan

Most factories use UV-curing acrylic resin, which provides a hard, glossy, and durable surface.

Internal Structure of PU Stone Panel

A typical PU stone panel consists of 3 main layers and optional additives.

(1) Outer UV Coating

Hard, glossy or matte protective layer.

(2) Stone Texture Surface

Printed film or sprayed color.

(3) PU Foam Core

Main structure, providing insulation and lightweight strength.

Optional Additives

- Fire retardant

- Soundproofing particles

- Reinforced mesh

- Waterproof treatment

- Emboss texture layer

This multi-layer structure makes PU stone panels stronger and more durable than most foam decorative panels.

Why These Materials Make PU Stone Panels Superior

Because of its material combination, PU stone panel offers unique benefits that natural stone, PVC stone panels, and WPC wall panels cannot achieve.

Below is a detailed comparison.

4.1 Lightweight Yet Strong

- PU density: 35–55 kg/m³

- Natural stone density: 2400–2600 kg/m³

This means PU stone panels are 95% lighter than real stone.

A single PC of PU panel weighs only 1–3 kg, allowing use in:

- Prefab houses

- Interior decoration

- Old building renovation

- High-rise installation

No reinforcement required, reducing labor cost.

4.2 Excellent Thermal and Sound Insulation

PU foam is one of the best insulating materials in construction, widely used in:

- Cold storage

- Refrigerators

- Insulation boards

- Prefabricated walls

PU stone panels therefore reduce energy consumption in buildings.

4.3 Waterproof and Moisture-Proof

The closed-cell PU structure is naturally water-resistant. This prevents:

- Mold growth

- Material swelling

- Water absorption

It performs perfectly in humid areas such as:

- Basements

- Bathrooms (non-direct water areas)

- Coastal regions

4.4 Long-Lasting Outdoor Durability

Thanks to the UV layer and PU stability, PU stone panels resist:

- Sunlight

- Rain

- Snow

- High temperatures

- Low temperatures

Outdoor lifespan can reach 10–20 years with proper installation.

4.5 Easy & Fast Installation

Materials allow:

- Nail fixation

- Glue fixation

- Joint-free installation

- DIY installation

An average worker can install 20–35 m² per day.

4.6 Environmental Advantages

Compared with real stone, PU stone panels:

- Reduce mining

- Reduce transportation emissions due to lower weight

- Use recyclable PU material

- Contribute to sustainable decoration solutions

Raw Materials Used in PU Stone Panel Production

Here is a detailed list of the materials used in the manufacturing process.

5.1 PU Chemical Materials

Polyol: Base chemical providing flexibility

MDI (Isocyanate): Reacts with polyol to form PU foam

Foaming agent: Produces the lightweight internal structure

Catalyst: Controls reaction speed

Surfactant: Ensures stable foam

Fire retardant additives: Improve safety standards

5.2 Coating & Surface Materials

- PVC decorative film

- Acrylic paint

- Stone texture powder

- Metallic pigments

- Primer coating

- Sealant coating

5.3 Protective Materials

- UV-curable resin

- Hard coating additives

- Anti-scratch particles

5.4 Structural Additions (Optional)

- Fiberglass mesh

- Anti-crack layer

- Waterproof topcoat

How PU Stone Panels Are Manufactured

Understanding the materials also means understanding the production process.

Below is a simplified production flow.

6.1 Mold Preparation

- Aluminum or steel molds

- 3D engraved stone texture

- Heat-controlled mechanisms

Molds determine pattern, size, and realism.

6.2 PU Injection & Foaming

PU mixture (polyol + MDI + foaming agent) is:

Injected into the mold

Expanded and cured

Formed into a solid foam shape

This step defines:

- Density

- Strength

- Texture depth

6.3 Surface Application

Depending on the manufacturer:

Method A: HD Printing Film Transfer

- Film placed onto surface

- Heat transfer process

- Color fixed onto PU panel

Method B: Multi-Layer Spraying

- Primer sprayed

- Texture layer applied

- Natural color sprayed

- Artistic detailing added

6.4 UV Coating Application

After the surface is ready:

- UV coating sprayed

- UV curing machine hardens surface

- Anti-scratch layer formed

6.5 Quality Inspection

Tests include:

- Color consistency

- Surface hardness test

- Drop test

- Water absorption test

- UV aging test

- Fire retardant level

6.6 Cutting, Packaging & Shipping

Panels are:

- Trimmed

- Checked

- Packed with bubble film

- Loaded into cartons

- Palletized for export

Technical Specifications of PU Stone Panels

Typical parameters:

| Item | Value |

|---|---|

| Density | 35–55 kg/m³ |

| Thickness | 15–40 mm |

| Length | 1000–3000 mm |

| Width | 300–600 mm |

| Waterproof | Yes |

| Thermal Conductivity | 0.024–0.030 W/(m·K) |

| Fire Rating | B1/B2 (depends on additives) |

| UV Resistance | 2000–3000 hours |

| Life Span | 10–20 years |

Why Global Buyers Choose PU Stone Panels

Because of the material advantages, PU stone panels are now widely used in:

- Villa exterior walls

- Prefabricated house construction

- Garden landscape walls

- Hotel interior decoration

- Retail and coffee shop decoration

- Boutique and restaurant walls

- Community fences

They combine aesthetics, durability, and cost efficiency—making them ideal for importers and project contractors.

Key Material Advantages Compared to Other Wall Materials

Here is a comparison of PU stone panel materials with other materials:

| Material | Weight | Waterproof | Insulation | Realistic Texture | Price |

|---|---|---|---|---|---|

| PU Stone Panel | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★☆ | Medium |

| Natural Stone | ★★☆☆☆ | ★★★★★ | ★★☆☆☆ | ★★★★★ | High |

| PVC Panel | ★★★☆☆ | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ | Low |

| WPC Panel | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | ★★★☆☆ | Medium |

| Fiber Cement Panel | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | Medium |

PU stone panels offer the most balanced cost-performance ratio.

Conclusion: What PU Stone Panels Are Made Of

To summarize, PU stone panels are primarily made of:

High-density polyurethane (PU) foam core

High-definition stone texture film or sprayed coating

UV protective layer

These materials together create:

- Lightweight structure

- Realistic stone appearance

- Thermal insulation

- Waterproof performance

- Long-lasting durability

- Easy installation

This makes PU stone panel a superior alternative to natural stone and traditional wall materials for modern architecture and decoration.