PS Wall Panel, short for Polystyrene Wall Panel, is a decorative and functional construction material made from polystyrene (PS), a synthetic polymer. PS wall panels are gaining traction in the building and interior design industries due to their affordability, ease of installation, and excellent physical properties. These panels are widely used in both residential and commercial projects for a range of applications, offering an eco-friendly, cost-effective alternative to traditional building materials like drywall, plaster, and tiles.

This detailed guide provides a thorough understanding of PS wall panels, including their production process, features, applications, advantages, and emerging trends in the market.

Table of Contents

ToggleDefinition of PS Wall Panels

PS wall panels are prefabricated panels made primarily from polystyrene, a thermoplastic polymer. The key feature of PS panels is their lightweight construction, which makes them easier to handle, transport, and install compared to heavier materials like concrete or traditional drywall. These panels are available in various designs, finishes, and sizes, allowing them to be customized for a wide range of applications.

Polystyrene is chosen for its insulating properties, durability, and ease of molding into different shapes and sizes. The material is used in both rigid and foam forms, with foam-based panels often featuring a cellular structure that enhances their insulation capabilities.

Production Process of PS Wall Panels

The production of PS wall panels involves several steps, from material preparation to final surface treatments. Below is a detailed breakdown of the key stages in the manufacturing process:

1.Raw Material Preparation

Polystyrene pellets or beads are the primary raw material used in the production of PS wall panels. These pellets are typically derived from petroleum-based monomers, but environmentally friendly alternatives are being explored. The raw polystyrene is chosen for its lightweight properties, thermal insulation capacity, and ease of processing.

2.Extrusion Molding

Once the raw materials are prepared, they are heated and melted to form a homogeneous plastic mass. The molten polystyrene is then fed into an extrusion machine, where it is shaped into continuous sheets or profiles. This process ensures that the material has a consistent thickness and smooth surface, making it suitable for further processing.

The extrusion process can also incorporate additives such as fire retardants, UV stabilizers, and colorants to enhance the panel’s properties. For example, fire-resistant PS panels are manufactured by introducing flame retardant chemicals into the mix during extrusion.

3.Foaming (Optional)

Some PS wall panels are made from foamed polystyrene, where gas is introduced into the molten polymer to create a cellular structure. This step is essential for improving the insulation properties of the panel. The foamed structure also adds to the lightweight nature of the material, which is one of the main advantages of PS panels.

4.Surface Treatment

After the panel is formed, various surface treatments are applied to enhance its aesthetic appeal and functionality. These treatments may include:

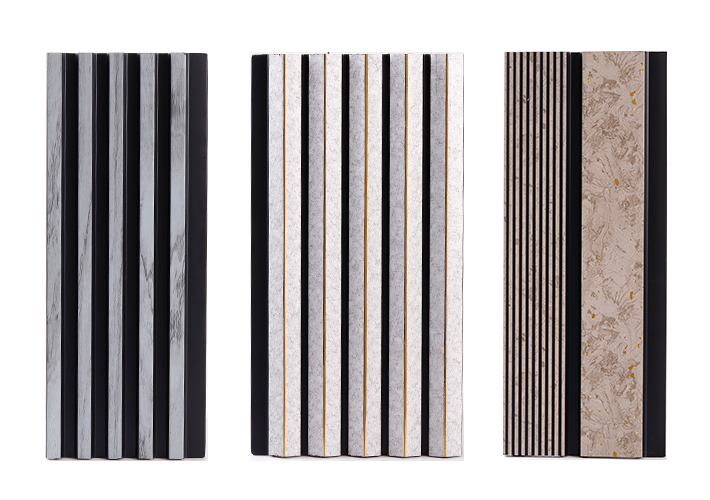

- Lamination: The panel surface is coated with a decorative layer, such as laminate, PVC, or metal films, which can mimic the appearance of natural materials like wood, stone, or marble.

- Embossing: Patterns or textures can be pressed onto the surface to create unique finishes that add visual interest.

- UV Printing: In some cases, high-definition digital printing techniques are used to create custom designs, patterns, or graphics on the panels.

- Coating: Protective coatings may be applied to improve the durability and resistance of the panels against UV degradation, scratches, or moisture.

5.Cutting and Shaping

Once the panels are extruded and treated, they are cut into the desired lengths and shapes based on customer specifications. Some manufacturers offer custom sizes to meet specific project requirements, such as wall coverings for unique architectural features or spaces with irregular dimensions.

Features of PS Wall Panels

PS wall panels offer a variety of features that make them appealing for both residential and commercial applications. Some of the key characteristics include:

1.Lightweight and Easy to Handle

One of the standout features of PS wall panels is their lightweight nature. This makes them easier to transport, handle, and install compared to traditional building materials like cement or plaster. The reduced weight also lowers transportation costs and minimizes the labor required for installation, which can lead to significant cost savings for contractors.

2.Thermal Insulation

Polystyrene has inherent insulating properties, making PS wall panels an excellent choice for improving the energy efficiency of buildings. By reducing heat transfer through walls, these panels help maintain a comfortable indoor temperature and reduce the need for air conditioning or heating, resulting in lower energy consumption and utility bills.

3.Waterproof and Moisture-Resistant

PS wall panels are highly resistant to water and moisture, making them ideal for use in areas prone to humidity, such as bathrooms, kitchens, and basements. This moisture resistance also helps prevent the growth of mold and mildew, which can damage traditional building materials.

4.Sound Insulation

PS panels also provide sound insulation benefits due to their dense structure, which helps to reduce noise transmission between rooms. This feature is particularly valuable in commercial spaces or multi-family residential buildings where soundproofing is important.

5.Durability and Longevity

Despite their lightweight nature, PS wall panels are durable and resistant to physical wear and tear. They do not crack or degrade easily, even in challenging environmental conditions, making them a long-lasting solution for both interior and exterior applications.

6.Eco-Friendly

Polystyrene is a recyclable material, and many manufacturers now focus on producing PS wall panels that are fully recyclable at the end of their life cycle. Additionally, the energy savings provided by these panels contribute to their eco-friendly appeal.

7.Cost-Effective

Compared to traditional building materials like wood, concrete, or marble, PS wall panels are highly cost-effective. Their affordability, combined with the ease of installation and low maintenance costs, makes them an attractive option for both residential and commercial projects.

Applications of PS Wall Panels

PS wall panels are used in a wide range of applications, thanks to their versatility and cost-effectiveness. Some common uses include:

1.Interior Decoration

PS panels are often used for creating decorative wall coverings in residential interiors. Their ability to mimic the appearance of natural materials such as wood, marble, or stone allows homeowners and designers to achieve high-end looks without the associated costs.

2.Commercial Spaces

In commercial settings, PS wall panels are used in offices, retail stores, hotels, and restaurants to enhance the aesthetic appeal of the space. Their ease of installation and variety of finishes make them popular in high-traffic areas where durability and cost-effectiveness are essential.

3.Moisture-Prone Areas

PS wall panels are ideal for moisture-prone environments, such as bathrooms, kitchens, and laundry rooms. Their resistance to water, mold, and mildew ensures a long-lasting finish in spaces exposed to high humidity.

4.Exterior Cladding

Some PS panels are also used for exterior cladding on buildings. While they are typically used in less harsh weather conditions, with additional UV-protective coatings, they can be utilized for façades, giving buildings an aesthetically pleasing and low-maintenance exterior.

5.Soundproofing

Due to their sound insulation properties, PS wall panels are used in soundproofing applications, such as in music studios, theaters, or offices in noisy environments. They help create quieter, more comfortable spaces by reducing external noise.

Future Trends in PS Wall Panels

1.Increased Sustainability

As environmental concerns continue to grow, there is a rising demand for sustainable building materials. PS wall panels are expected to evolve to become even more eco-friendly, with advancements in recycling technologies and the use of biodegradable additives in their production.

2.Technological Innovations

The ongoing development of advanced production technologies will likely improve the performance of PS wall panels. Innovations in flame retardancy, impact resistance, and moisture resistance will broaden the potential applications of PS panels, particularly in more demanding environments.

3.Smart Features

In the future, PS wall panels may integrate smart features, such as temperature-regulating coatings or embedded sensors for monitoring environmental conditions. These advancements could make PS panels even more versatile and appealing for modern, tech-savvy consumers.

4.Expansion into Emerging Markets

As construction and renovation activities increase in emerging markets, PS wall panels are likely to gain popularity due to their affordability and practicality. This trend is particularly evident in regions like Asia, Africa, and South America, where the demand for cost-effective building materials is on the rise.

Conclusion

PS wall panels represent a highly versatile and cost-effective solution for modern construction and decoration needs. Their lightweight, durable, and customizable properties make them an excellent choice for both residential and commercial applications. As technology advances and sustainability becomes a central focus in the building materials industry, PS wall panels are expected to play an increasingly important role in shaping the future of construction. Whether you’re a homeowner, contractor, or supplier, understanding the benefits of PS wall panels can help you make informed decisions for your next project.