Table of Contents

ToggleIntroduction

Wood Plastic Composite (WPC) materials have revolutionized the construction and interior design industries with their excellent durability, aesthetic appeal, and eco-friendliness. Among the many WPC products available today, WPC Timber Tubes stand out for their unique combination of beauty and functionality. They are widely used in architectural decoration, commercial facades, interior wall partitions, and outdoor shading systems.

For importers, builders, and designers, one of the most frequently asked questions is:

👉 What are the common sizes of WPC Timber Tube?

Understanding the size range and specifications of WPC Timber Tubes is essential for selecting the right type for different applications. This article provides a comprehensive guide covering the standard sizes, customization options, applications, installation tips, and factors influencing size selection, helping you make an informed purchasing decision — whether you’re a contractor, wholesaler, or architectural designer.

What Is a WPC Timber Tube?

Before we dive into sizes, it’s important to understand what a WPC Timber Tube is.

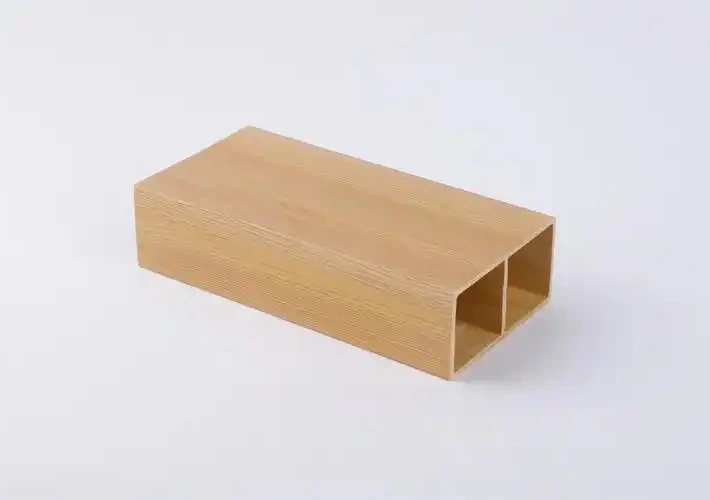

A WPC Timber Tube is a hollow structural decorative profile made from a blend of wood fiber (around 40–60%), plastic resin (such as PE or PVC), and additives for UV resistance, color stability, and strength. The result is a material that looks like natural wood but performs much better in terms of moisture resistance, durability, and maintenance.

Main Characteristics:

- Eco-friendly: Made from recycled wood and plastic.

- Durable: Resistant to water, rot, and insects.

- Low maintenance: No painting or polishing required.

- Versatile: Suitable for both indoor and outdoor applications.

- Aesthetic appeal: Natural wood-like texture and color options.

Standard Sizes of WPC Timber Tubes

WPC Timber Tubes come in a variety of sizes and shapes to suit different decorative and structural needs. The dimensions mainly depend on application type — whether it’s for interior ceilings, wall partitions, exterior facades, or shading panels.

Below are some commonly used sizes (in millimeters):

| Model | Width (mm) | Height (mm) | Thickness (mm) | Length (mm) | Shape |

|---|---|---|---|---|---|

| TT40x80 | 40 | 80 | 2.0–3.0 | 2900 / 3000 | Rectangular |

| TT50x100 | 50 | 100 | 2.0–3.5 | 2900 / 3000 | Rectangular |

| TT50x150 | 50 | 150 | 3.0–4.0 | 2900 / 3000 | Rectangular |

| TT60x60 | 60 | 60 | 2.5–3.0 | 2900 / 3000 | Square |

| TT80x80 | 80 | 80 | 3.0–4.0 | 2900 / 3000 | Square |

| TT100x100 | 100 | 100 | 3.0–5.0 | 2900 / 3000 | Square |

| TT40x100 | 40 | 100 | 2.5–3.0 | 2900 / 3000 | Rectangular |

| TT30x60 | 30 | 60 | 2.0 | 2900 / 3000 | Rectangular |

| TT60x120 | 60 | 120 | 3.0 | 2900 / 3000 | Rectangular |

| TT25x50 | 25 | 50 | 2.0 | 2900 / 3000 | Rectangular |

These are standard factory models that are mass-produced for commercial and residential projects.

However, manufacturers (like our WPC Timber Tube factory in China) can also customize sizes according to your architectural design drawings.

Customization Options

In addition to standard models, WPC Timber Tubes can be customized in several aspects:

(1) Dimensions

Manufacturers can produce custom widths, heights, and wall thicknesses based on your requirements. For example:

- Larger tubes (e.g., 100×200 mm) for exterior facades or shading systems.

- Smaller tubes (e.g., 30×60 mm) for indoor ceilings or wall partitions.

(2) Surface Finish

- Wood grain embossing

- Brushed surface

- 3D texture

- Matte or glossy finish

(3) Color Options

Available in natural and modern tones such as:

- Teak

- Walnut

- Cedar

- Charcoal grey

- Coffee

- Light oak

Custom color matching (based on RAL or Pantone color code) is also available for large projects.

(4) Length

Standard lengths are 2.9m or 3.0m, but customized lengths (up to 5.8m) can be produced for container-based export.

Applications of WPC Timber Tubes

WPC Timber Tubes have become an essential decorative element in modern architecture due to their design flexibility and visual appeal. Let’s look at some of the major application scenarios.

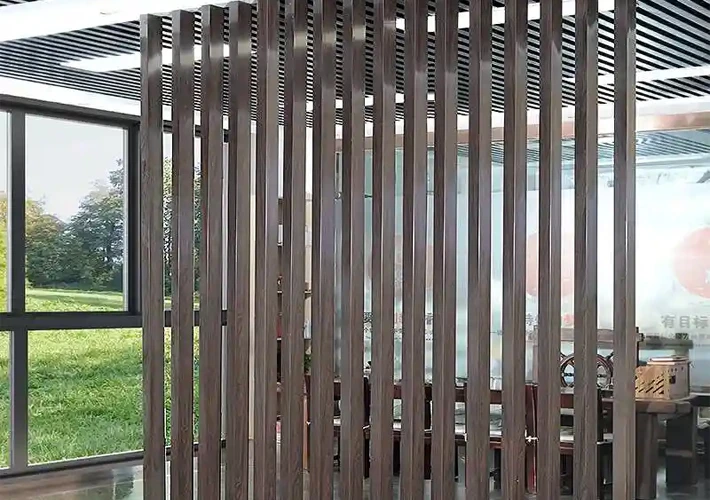

(1) Interior Decoration

- Ceiling Beams and Grilles: Used in hotels, offices, and malls to create a warm wooden ambiance.

- Wall Partitions: Offers a lightweight and stylish partition solution for open spaces.

- Feature Walls: Adds texture and depth to interior design.

(2) Exterior Architecture

- Building Facades: Provides a natural wood look with excellent UV and weather resistance.

- Sunshade Louvers: Controls sunlight and enhances energy efficiency.

- Pergolas & Gazebos: Durable and aesthetic structural elements.

(3) Commercial Spaces

- Shopping malls, airports, and exhibition halls often use WPC Timber Tubes for acoustic design and visual zoning.

(4) Hospitality and Residential Projects

- Hotels, resorts, and modern homes adopt WPC tubes to combine functionality with luxury aesthetics.

Factors to Consider When Choosing WPC Timber Tube Sizes

Selecting the right size of WPC Timber Tube depends on several key factors:

(1) Design Aesthetics

Larger tubes (like 100×150 mm) give a bold architectural appearance, while smaller ones (like 40×80 mm) offer a delicate visual texture.

(2) Structural Function

If used for shading or load-bearing decoration, thicker and larger sections are preferable.

For purely decorative indoor use, thinner and smaller models suffice.

(3) Installation Space

Measure ceiling height or wall dimensions before selecting sizes to maintain proper proportions and harmony.

(4) Ventilation and Light

Open spacing between tubes affects airflow and lighting effects — spacing and tube dimensions must align with design intent.

(5) Cost and Material Usage

Larger and thicker tubes require more material, which slightly increases cost and shipping weight. Choose based on your project budget.

Advantages of Using WPC Timber Tubes

WPC Timber Tubes are increasingly replacing traditional wood and aluminum decorative profiles. Here’s why:

(1) Durability and Weather Resistance

Unlike natural wood, WPC tubes do not warp, crack, or rot under humidity and temperature changes.

(2) Maintenance-Free

No need for painting or polishing — just occasional cleaning keeps them looking new.

(3) Fire Retardant & Termite-Proof

WPC materials include additives that resist flame spread and prevent insect damage.

(4) Easy Installation

Lightweight hollow structure makes handling and mounting easier using aluminum clips and accessories.

(5) Eco-Friendly

Made from recycled wood and plastic, helping reduce deforestation and waste.

(6) Aesthetic Flexibility

Multiple colors, grains, and surface textures allow WPC Timber Tubes to match any modern design style — from minimalist to luxurious.

WPC Timber Tube Size Selection by Application Scenario

To simplify your choice, here’s a guide suggesting recommended sizes for different uses:

| Application Area | Recommended Size (mm) | Notes |

|---|---|---|

| Indoor Ceiling Decoration | 30×60 / 40×80 | Light, elegant look |

| Indoor Wall Partition | 40×80 / 50×100 | Structural stability |

| Hotel Lobby or Hall Feature Wall | 50×150 / 60×120 | Premium design |

| Outdoor Facade Cladding | 80×80 / 100×100 / 100×150 | High weather resistance |

| Pergola / Sunshade System | 60×120 / 80×150 / 100×200 | Structural durability |

| Commercial Building Exterior | 80×80 / 100×100 | Modern architectural finish |

Installation Tips for WPC Timber Tubes

Proper installation ensures the best performance and aesthetics. Here are key recommendations:

(1) Preparation

- Ensure wall or ceiling surface is clean, dry, and flat.

- Plan spacing and layout before drilling.

(2) Fixing System

Use aluminum alloy frames or stainless steel brackets for strong and long-lasting support.

(3) Expansion Gap

Leave a 3–5 mm gap for thermal expansion between each tube.

(4) Cutting & Drilling

Use woodworking tools with fine blades to achieve clean cuts.

(5) Finishing

End caps or edge trims can be used to hide openings for a neat finish.

How WPC Timber Tube Sizes Affect Cost and Logistics

When exporting WPC Timber Tubes, size selection directly influences container loading efficiency and transportation costs.

- Standard 3.0m length allows for optimized loading into 20ft or 40ft containers.

- Larger section tubes take up more space, reducing total loading quantity.

- Smaller models (e.g., 40×80 mm) can fit more pieces per pallet, lowering unit freight cost.

Thus, balancing size selection with shipping efficiency is key for international wholesalers.

Market Trends of WPC Timber Tubes

The global market for WPC decorative materials is growing rapidly, particularly in North America, Europe, and Southeast Asia. Architects and builders are increasingly specifying WPC Timber Tubes for green and modern design projects.

Key Trends:

- Bigger Profiles: More architects prefer wide and tall tube designs for bold facades.

- Customized Colors: Dark walnut, charcoal, and matte finishes are trending.

- Sustainability Focus: Eco-certifications (like FSC, RoHS, and CE) are becoming project requirements.

As a leading WPC Timber Tube manufacturer in China, we have witnessed increased demand for customized dimensions and surface textures tailored to overseas architectural needs.

Why Choose a Professional WPC Timber Tube Supplier from China

Choosing a reliable Chinese factory ensures quality consistency, competitive pricing, and timely delivery.

Our Factory Advantages:

- Advanced extrusion equipment ensures uniform tube dimensions.

- Strict quality control on raw materials and finished products.

- OEM & ODM services available for custom designs.

- Bulk export experience with clients across the USA, Canada, Australia, and Europe.

- Comprehensive accessory systems for quick installation.

By sourcing directly from a WPC Timber Tube manufacturer in China, you can save costs and ensure stable supply for large-scale building projects.

Conclusion

WPC Timber Tubes are the perfect combination of aesthetic value, structural functionality, and environmental sustainability. Understanding their common sizes and specifications helps you choose the right model for each project, ensuring both design integrity and performance.

To summarize:

- Standard sizes range from 30×60 mm to 100×200 mm, length typically 2.9–3.0 meters.

- Sizes can be customized for special architectural applications.

- Different sizes suit various use cases — from indoor ceilings to outdoor facades.

- Proper selection and installation ensure long-term durability and visual harmony.

If you’re a contractor, wholesaler, or project designer looking for high-quality WPC Timber Tubes, choosing a trusted Chinese supplier ensures you get competitive prices, custom options, and professional export support.

Contact Us

We are a leading WPC Timber Tube manufacturer and exporter in China, specializing in customized decorative materials for architectural and interior projects.

📞 Contact us today to get the latest WPC Timber Tube catalog, free samples, and competitive factory prices — and let’s build your next project together!