Table of Contents

ToggleIntroduction

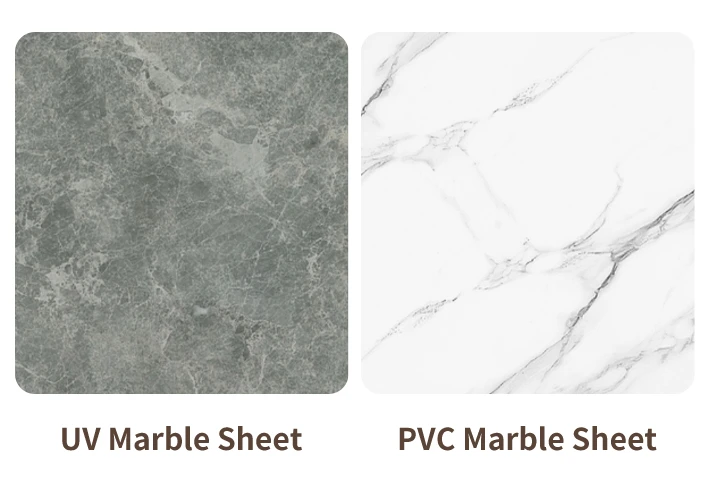

In the decorative materials industry, marble sheet panels have become an increasingly popular choice for both residential and commercial projects. Among the various types available on the market, UV Marble Sheets and PVC Marble Sheets are the two most widely used.

At first glance, these products may look similar — both mimic the luxurious appearance of natural marble while being lighter, easier to install, and more affordable. However, the material composition, production processes, performance characteristics, and pricing differ significantly.

This article provides a comprehensive comparison between UV Marble Sheets and PVC Marble Sheets, helping wholesalers, importers, and contractors make informed purchasing decisions.

What is PVC Marble Sheet?

2.1 Definition

PVC Marble Sheet is a decorative wall panel made from polyvinyl chloride (PVC) resin combined with calcium carbonate powder and various additives. It features a printed marble pattern layer and a UV-coated surface for enhanced durability.

2.2 Production Process

- Raw Material Mixing – PVC resin + calcium carbonate + stabilizers + pigments are mixed.

- Extrusion – The mixture is extruded into flat sheets.

- Lamination – A decorative film with a marble design is laminated using hot pressing.

- UV Coating – A UV-curable coating is applied to improve surface hardness, scratch resistance, and gloss.

- Cutting & Packaging – Sheets are trimmed to the required size and packed for shipment.

2.3 Features

- Thickness: 2.5 mm – 5 mm (common for wall applications)

- Lightweight and easy to install

- Cost-effective compared to natural stone

- Waterproof, termite-proof, and corrosion-resistant

- Wide variety of colors and patterns

What is UV Marble Sheet?

3.1 Definition

UV Marble Sheet refers to a high-gloss decorative panel made by coating the surface of a base sheet (often PVC, MDF, or SPC) with a UV-curable coating layer. The key difference is that UV Marble Sheets typically have a thicker and more advanced UV coating compared to standard PVC Marble Sheets, resulting in enhanced surface hardness, gloss, and scratch resistance.

3.2 Production Process

- Base Material Preparation – Can be PVC sheet, MDF board, or SPC sheet.

- Decorative Film Lamination – High-definition marble design film is applied.

- Multiple UV Coating Layers – Several layers of UV-curable paint are rolled or sprayed onto the surface.

- UV Curing – Each layer is cured under UV lamps for durability and gloss.

- Polishing & Finishing – The surface is polished for mirror-like shine.

3.3 Features

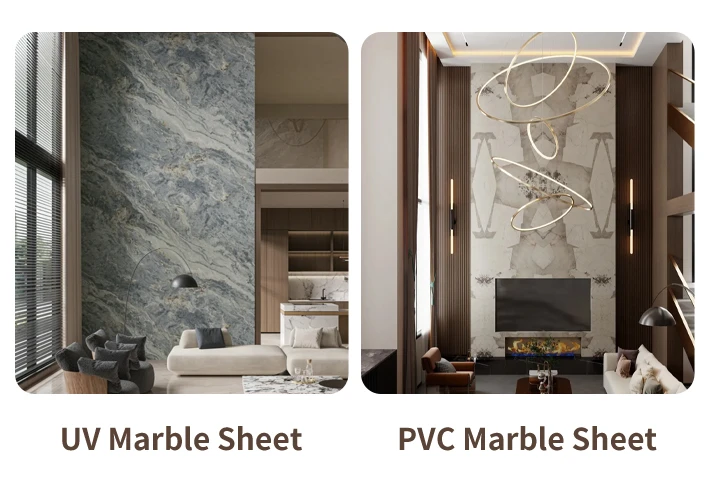

- Higher gloss and better color depth than PVC Marble Sheets

- Extremely smooth and reflective surface

- Surface hardness can reach 3H–6H, providing better scratch resistance

- More durable against fading and discoloration

Key Differences Between UV Marble Sheet and PVC Marble Sheet

| Feature | PVC Marble Sheet | UV Marble Sheet |

|---|---|---|

| Base Material | Pure PVC composite | PVC, MDF, or SPC |

| Surface Finish | Printed marble film + thin UV layer | Thick, multi-layer UV coating |

| Gloss Level | Moderate gloss (50–80 GU) | High gloss (80–130 GU) |

| Surface Hardness | 2H–3H | 3H–6H |

| Durability | Good for normal indoor use | Better for high-traffic areas |

| Cost | Lower | Higher |

| Applications | Residential walls, ceilings | Luxury interiors, commercial spaces |

| UV Resistance | Good | Excellent |

| Scratch Resistance | Medium | High |

| Weight | Light | Slightly heavier (due to coating) |

Advantages of PVC Marble Sheet

Affordable – Lower cost makes it suitable for large-scale projects.

Lightweight – Easier transport and installation, reducing labor costs.

Variety of Designs – Wide selection of marble patterns and textures.

Waterproof & Termite-Proof – Perfect for humid environments.

Easy Maintenance – Wipe clean with mild detergent.

Advantages of UV Marble Sheet

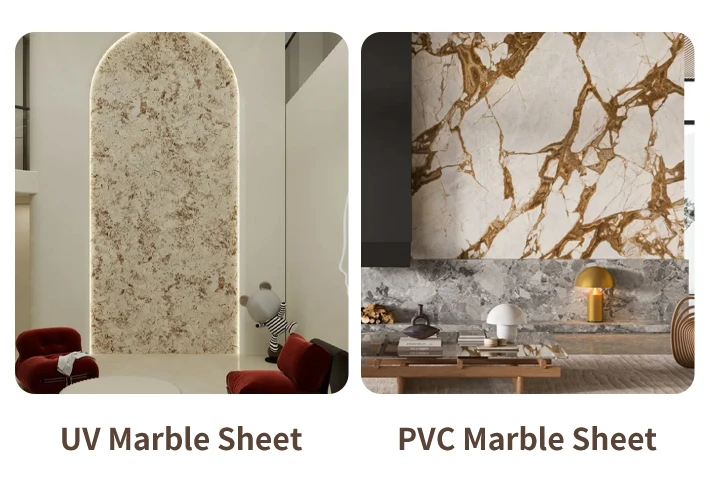

Superior Gloss and Aesthetic Appeal – Looks closer to polished natural marble.

High Surface Hardness – More resistant to scratches and wear.

Better Color Retention – UV coating prevents yellowing and fading over time.

Premium Feel – Ideal for luxury projects requiring a high-end finish.

Longer Service Life – More resistant to damage in high-traffic areas.

Disadvantages

PVC Marble Sheet

- Lower scratch resistance compared to UV Marble Sheets

- May look less “luxurious” in high-end applications

- Thin UV layer can wear off faster in heavy-use areas

UV Marble Sheet

- Higher cost, which may be a barrier for budget projects

- Slightly heavier and may require stronger adhesive or support

- Limited flexibility compared to pure PVC sheets

Application Scenarios

PVC Marble Sheet

- Residential Walls & Ceilings

- Hotel Rooms

- Retail Store Decoration

- Kitchen Backsplashes (non-heat zones)

- Bathroom Walls

UV Marble Sheet

- Luxury Hotel Lobbies

- Showrooms & Boutiques

- Office Reception Areas

- High-End Restaurants

- Exhibition Booths

Market Demand & Trends

PVC Marble Sheet demand remains high in Southeast Asia, Africa, and Middle East markets where cost efficiency is crucial.

UV Marble Sheet is gaining popularity in Europe, North America, and premium markets where aesthetics and durability are prioritized.

Sustainability Trend – Manufacturers are adopting lead-free stabilizers and eco-friendly coatings to meet environmental regulations.

Price Comparison (2024 Data)

| Product | FOB China Price Range | Main Buyers |

|---|---|---|

| PVC Marble Sheet (3mm–5mm) | USD 4.5 – 7.5 / m² | Southeast Asia, Africa, Middle East |

| UV Marble Sheet (3mm–5mm) | USD 6.5 – 10.5 / m² | Europe, North America, Middle East luxury projects |

Which One Should You Choose?

- Choose PVC Marble Sheet if:

- Budget is limited

- Project is in a residential or low-traffic commercial setting

- You prioritize cost efficiency over ultra-high gloss

- Choose UV Marble Sheet if:

- You want a premium, high-gloss finish

- Project is in a high-traffic or luxury environment

- You prioritize durability and scratch resistance

Conclusion

Both UV Marble Sheets and PVC Marble Sheets offer unique advantages. PVC Marble Sheet is more budget-friendly and versatile for everyday projects, while UV Marble Sheet delivers a more premium appearance and longer-lasting performance for luxury spaces.

The “better” choice depends entirely on project requirements, budget constraints, and target market preferences.

For wholesalers and contractors, offering both options can maximize business opportunities and meet diverse client demands.