Table of Contents

ToggleIntroduction

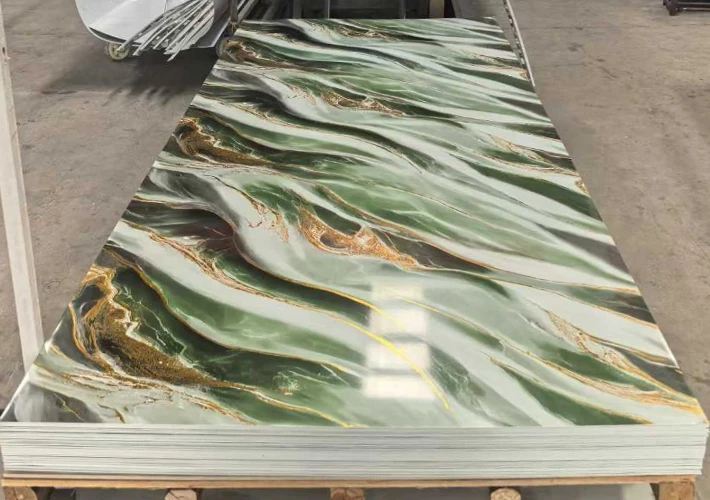

With the development of decorative materials, PVC marble sheets have become a popular alternative to natural marble in both residential and commercial interior decoration. They offer an ideal combination of aesthetics, durability, and cost-effectiveness. One of the key technologies that brings the vivid, realistic stone-like appearance to these sheets is transfer printing technology. This advanced surface treatment not only enhances the visual appeal of PVC sheets but also increases their market competitiveness.

This article provides a comprehensive overview of the transfer printing technology used in PVC marble sheets, including its principles, process, advantages, and market implications.

What Is Transfer Printing Technology?

Transfer printing, also known as heat transfer printing, is a technique that transfers a pre-printed design or image from a carrier (usually a film or paper) onto a substrate (such as a PVC sheet) using heat and pressure. This process allows complex and high-resolution patterns to be applied to the surface of various materials with excellent fidelity.

In the context of PVC marble sheets, transfer printing is primarily used to replicate the natural textures and veining of real marble, granite, onyx, and other stones.

Basic Principles of Transfer Printing

The process involves the following core principles:

- Heat Activation: Heat softens the ink or pigment on the transfer film or paper.

- Pressure Application: Pressure is applied to ensure the ink adheres uniformly to the PVC substrate.

- Adhesion and Release: Special adhesives or coatings help bond the ink to the surface, and once cooled, the film is peeled off, leaving the pattern on the sheet.

The success of this process depends on careful control of temperature, time, pressure, and materials used.

Process Flow of Transfer Printing on PVC Marble Sheets

The production of transfer-printed PVC marble sheets generally follows this sequence:

1.Base Sheet Preparation

- A rigid PVC sheet (also known as PVC foam board) is extruded or calendered to the desired thickness and size.

- Surface is cleaned and sometimes coated with a primer to ensure good adhesion.

2.Printing of Transfer Film

- The desired marble pattern is printed onto a special transfer film using gravure printing or digital printing.

- Inks used are heat-sensitive and formulated to bond with PVC surfaces.

3.Transfer Printing (Lamination)

- The transfer film is placed in contact with the PVC sheet surface.

- Heat and pressure are applied using a laminating machine or heat press, usually at 160–180°C.

- The design is transferred from the film to the sheet.

4.Cooling and Film Removal

- Once cooled, the film is peeled off, leaving behind the printed pattern on the PVC surface.

5.Surface Treatment

- A UV coating or lamination is often added for wear resistance, waterproofing, and gloss enhancement.

- Some manufacturers apply additional anti-scratch or anti-bacterial coatings.

Types of Transfer Printing Used in PVC Marble Sheets

1.Dry Transfer Printing

- Uses dry-printed transfer films.

- Offers high accuracy and vivid color reproduction.

- Commonly used for large-scale industrial production.

2.Heat Transfer Foil Printing

- Incorporates metallic or glossy finishes.

- Suitable for decorative designs requiring a luxurious appearance.

3.Water Transfer Printing (Hydrographics) (Less common for flat panels)

- Primarily used on 3D surfaces.

- Not typically used for flat PVC marble sheets due to complexity and cost.

Advantages of Transfer Printing in PVC Marble Sheets

1.Realistic Aesthetics

Transfer printing allows replication of high-resolution images of real marble, including intricate veining, color variation, and depth, achieving a look very close to natural stone.

2.Design Flexibility

Manufacturers can customize patterns easily without changing the substrate. This allows for a wide variety of styles: classic marble, exotic stone, concrete, or even wood grain.

3.Cost-Efficiency

Compared to natural stone, transfer-printed PVC sheets are significantly cheaper in terms of both material and installation.

4.Environmental Friendliness

This process avoids the use of dyes that penetrate the PVC sheet, reducing chemical waste and pollution. Moreover, since the sheets are lightweight, they reduce carbon footprint during transportation.

5.Efficient Mass Production

The process is well-suited to industrial automation, making it ideal for high-volume production with consistent quality.

Application Scenarios

Transfer-printed PVC marble sheets are widely used in:

Interior Wall Cladding

In homes, hotels, shopping malls, and office buildings.

Ceiling Panels

Lightweight and easy to install, providing an elegant finish.

Kitchen and Bathroom Surfaces

Moisture-resistant and easy to clean.

Furniture Decoration

Used as surface skins for cabinets, wardrobes, and other modular furniture.

Commercial Fit-Out

Including elevator walls, reception counters, and retail display backdrops.

Comparison With Other Surface Technologies

| Feature | Transfer Printing | UV Printing | Lamination | Paint Coating |

|---|---|---|---|---|

| Resolution | High | Medium-High | Medium | Low-Medium |

| Cost | Medium | High | Low | Medium |

| Durability | High (with UV topcoat) | Medium | Medium | Low |

| Gloss Options | Multiple (matte, gloss) | Limited | Limited | Limited |

| Design Flexibility | Very High | High | Medium | Low |

Transfer printing strikes a balance between aesthetics, durability, and cost-effectiveness, making it the go-to choice for PVC marble sheet surfaces.

Key Factors Affecting Printing Quality

To ensure consistent and high-quality results, several factors must be controlled:

- Ink Quality – Must be heat-sensitive and bond well with PVC.

- Transfer Film – Must be dimensionally stable under heat and pressure.

- Machine Calibration – Temperature, pressure, and dwell time must be optimized.

- Surface Treatment – Primers and UV coatings improve adhesion and durability.

- Cleanroom Environment – Prevents dust and defects during printing.

Challenges in Transfer Printing Technology

- Color Fastness: Prolonged exposure to UV rays can cause color fading if not properly treated with UV coatings.

- Registration Issues: Misalignment during transfer can lead to defective sheets.

- Environmental Sensitivity: Temperature and humidity fluctuations in the factory can affect adhesion.

Future Trends and Market Outlook

1.Digitalization of Transfer Printing

Digital printing of transfer films allows for faster customization, shorter production cycles, and lower minimum order quantities (MOQ).

2.Eco-Friendly Inks and Coatings

With increasing environmental regulations, manufacturers are shifting to water-based or solvent-free inks and non-toxic coatings.

3.3D Textured Printing

Combining transfer printing with embossing or 3D texture layers can simulate not only the appearance but also the touch of real stone.

4.Integration with AI Design Systems

Some high-end manufacturers are using AI to generate custom marble patterns that can be transferred onto PVC sheets, offering unique designs for premium markets.

Case Study: Chinese Factories Leading the Way

China has become one of the global hubs for PVC marble sheet manufacturing, and many factories are equipped with advanced transfer printing lines. These facilities produce millions of square meters monthly and export to markets across the Middle East, Africa, Southeast Asia, and South America.

With competitive pricing and rapid turnaround times, these suppliers are setting new standards in the decorative panel industry. Some even offer OEM/ODM services with custom transfer printing capabilities for foreign clients.

Conclusion

Transfer printing technology plays a crucial role in the manufacturing of PVC marble sheets. It allows producers to deliver stunning, lifelike finishes with high efficiency, design versatility, and cost-effectiveness. As consumer demand continues to grow for eco-friendly and aesthetically pleasing materials, the importance of transfer printing will only increase in the PVC panel industry.

By understanding the principles, process, and future trends of transfer printing, manufacturers, distributors, and designers can better appreciate its value and potential in the decorative material market.