PS (Polystyrene) wall panels are gaining popularity in the decorative materials industry due to their lightweight, durable, and eco-friendly characteristics. In this article, we’ll dive deep into the production process and raw materials that make PS wall panels an excellent choice for modern interior design.

Table of Contents

ToggleOverview of PS Wall Panels

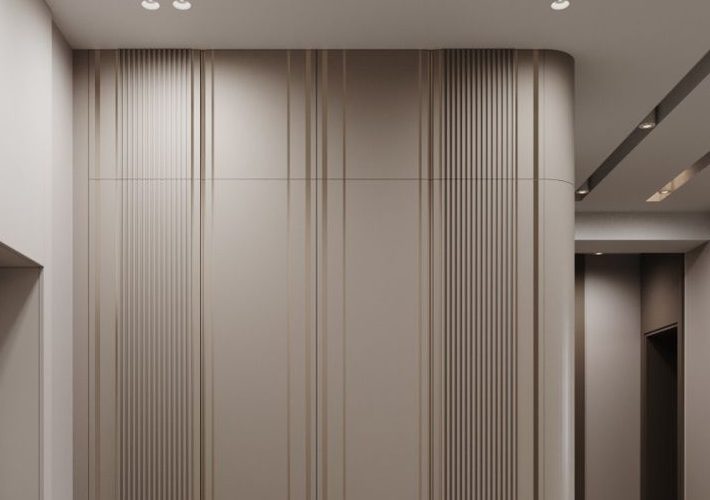

PS wall panels are decorative materials made from polystyrene, a versatile polymer. These panels are widely used for interior walls, offering a sleek and modern aesthetic with practical benefits such as insulation, soundproofing, and moisture resistance.

Raw Materials for PS Wall Panels

The production of PS wall panels involves a combination of polystyrene and other auxiliary materials to enhance their physical and chemical properties. Below are the main raw materials:

a. Polystyrene (PS)

Polystyrene is the primary raw material, known for its lightweight and moldable properties. It can be expanded or extruded to achieve specific characteristics like flexibility, rigidity, or insulation.

Types of Polystyrene Used:

- General-Purpose Polystyrene (GPPS): Offers transparency and rigidity.

- High-Impact Polystyrene (HIPS): Provides enhanced toughness and impact resistance.

b. Additives

To improve the performance of the panels, various additives are blended with the base material.

- Flame Retardants: Enhance fire resistance.

- UV Stabilizers: Protect the material from UV degradation.

- Pigments and Dyes: Add colors and patterns to match different aesthetic needs.

- Foaming Agents: Create lightweight, expanded structures for thermal and acoustic insulation.

c. Coating Materials

To enhance surface durability and aesthetics, PS wall panels are often coated with:

- PVC Films: For decorative finishes.

- UV Coating: For extra durability and resistance to fading.

d. Adhesives

Specialized adhesives are used during the lamination or bonding process to ensure structural integrity and longevity.

Production Process of PS Wall Panels

The production of PS wall panels is a complex process involving several stages, each critical to achieving the desired product quality. Below is a detailed breakdown of the steps:

Step 1: Raw Material Preparation

- Blending: Polystyrene is mixed with additives such as flame retardants, UV stabilizers, and pigments to prepare a homogenous blend.

- Foaming Agent Addition: If a lightweight panel is required, a foaming agent is incorporated into the mixture.

Step 2: Extrusion

- Melting: The blended material is fed into an extruder, where it is heated to its melting point (approximately 200°C).

- Shaping: The molten material is pushed through a die to form flat sheets or specific profiles for wall panels.

- Cooling: The extruded sheets are rapidly cooled using water or air to solidify their structure.

Step 3: Surface Lamination

- Film Application: Decorative PVC or other films are laminated onto the surface of the extruded PS sheet using heat and adhesive.

- UV Coating: An additional UV-protective layer is applied to enhance durability.

Step 4: Cutting and Shaping

- The laminated sheets are cut into specific dimensions based on market requirements. Advanced machinery ensures precision and minimizes material waste.

Step 5: Quality Control

- Dimensional Accuracy: Panels are checked for uniform thickness and precise dimensions.

- Surface Inspection: Ensures a smooth finish, free of defects like bubbles or scratches.

- Performance Tests: Panels are tested for fire resistance, UV resistance, and impact strength.

Step 6: Packaging

- Finished panels are carefully packed to prevent damage during transportation. Eco-friendly packaging materials are often used to align with sustainability goals.

Advantages of PS Wall Panels

The production process and material composition of PS wall panels result in several notable advantages:

a. Lightweight and Easy to Install

PS wall panels are lightweight, making them easy to transport and install, even in high-rise buildings.

b. Cost-Effective

Compared to traditional materials like wood or metal, PS panels are more affordable while offering similar aesthetic appeal.

c. Durable and Long-Lasting

Polystyrene is resistant to moisture, termites, and mildew, ensuring long-term performance in various environments.

d. Customizable Designs

The lamination process allows for various decorative finishes, including wood grain, marble patterns, or solid colors, to suit different interior styles.

e. Eco-Friendly

Recycled polystyrene can be used in production, reducing waste and the environmental footprint of the panels.

Applications of PS Wall Panels

PS wall panels have versatile applications across residential, commercial, and industrial spaces:

- Residential Use: Living rooms, bedrooms, and kitchens.

- Commercial Spaces: Offices, retail stores, and restaurants.

- Industrial Settings: Cleanrooms, warehouses, and temporary structures.

Innovations in PS Wall Panel Production

a. Advanced Extrusion Technology

Modern extrusion machines offer higher precision, enabling the production of panels with complex profiles and designs.

b. Sustainable Practices

Manufacturers are adopting green production practices, such as using renewable energy and incorporating recycled materials.

c. Enhanced Coating Techniques

Improved lamination and UV-coating technologies ensure better durability and aesthetics, meeting the increasing demand for high-performance wall panels.

Challenges in PS Wall Panel Production

Despite their advantages, PS wall panels face some challenges:

- Raw Material Price Volatility: The cost of polystyrene depends on global oil prices, affecting overall production costs.

- Environmental Concerns: While recyclable, improper disposal of polystyrene can harm the environment. Manufacturers must invest in recycling infrastructure.

Future Trends in PS Wall Panels

a. Smart Panels

Integration of smart technologies, such as embedded LED lighting or temperature sensors, is on the rise.

b. Increased Customization

Advanced printing and lamination techniques allow for highly personalized designs.

c. Growth in Sustainable Materials

Research is ongoing to develop bio-based alternatives to traditional polystyrene, enhancing the eco-friendliness of PS wall panels.

Conclusion

The production of PS wall panels involves a well-optimized process that combines advanced technology with high-quality raw materials. These panels are not only practical but also aesthetically pleasing, making them a preferred choice in modern construction and interior design. As innovation and sustainability continue to shape the industry, PS wall panels are poised to remain a vital part of the decorative materials market.