In global construction and renovation projects, rising labor costs have become one of the most critical challenges for developers, contractors, and investors.

In many overseas markets—such as Europe, the United States, Australia, Japan, and the Middle East—labor expenses often account for 30%–55% of total project costs, and in some interior fit-out or renovation projects, labor costs even exceed material costs.

As a result, more and more overseas buyers are asking a fundamental question:

Which building materials can truly reduce labor input and installation time?

This article analyzes the issue from a real overseas project perspective, focusing on construction efficiency, installation methods, systemized materials, and factory pre-fabrication, rather than simply listing product features.

Table of Contents

ToggleWhy Labor Costs Are So High in Overseas Construction Projects

Before discussing labor-saving materials, it is essential to understand why labor is so expensive overseas.

Hourly Wages Are High and Strictly Regulated

In many developed markets:

- General construction workers: USD 25–50 per hour

- Skilled trades (carpenters, electricians, tilers): USD 50–90 per hour

- Overtime, weekends, or night work: significantly higher

This means that any material requiring complex or slow installation will dramatically increase total project costs.

Highly Specialized Labor Increases Coordination Costs

Unlike some markets where one worker performs multiple tasks, overseas construction usually involves highly specialized labor divisions:

- Carpenters only do carpentry

- Electricians only handle wiring

- Tile installers only lay tiles

Materials that require:

- Multiple installation stages

- Wet works

- Frequent adjustments

- Coordination among different trades

will inevitably lead to higher labor consumption and longer project timelines.

Delays Equal Direct Financial Losses

In overseas projects, delays are not just scheduling issues:

- Delayed opening = lost rental income

- Extended site management = higher overhead

- Labor rescheduling = additional costs

Therefore, overseas clients increasingly prioritize materials that shorten installation time and reduce on-site uncertainty.

What Makes a Material Truly “Labor-Saving”?

Not all low-cost materials save labor. In overseas projects, a truly labor-saving material usually shares six core characteristics.

Dry Installation Instead of Wet Works

Materials that:

- Do not require cement or mortar

- Do not need curing or drying time

allow installation to proceed faster and more predictably.

Modular and System-Based Design

Standardized:

- Sizes

- Connection methods

- Accessories and trims

enable workers to follow clear installation steps rather than relying on craftsmanship experience.

Large-Format Coverage with Fewer Joints

Larger panels mean:

- Less cutting

- Fewer joints

- Faster alignment

which directly reduces labor hours.

High Tolerance for Substrate Conditions

Materials that:

- Can cover uneven or old walls

- Do not require perfect surface preparation

reduce both time and skill requirements.

High Level of Factory Pre-Fabrication

The more work completed in the factory—surface finishing, lamination, structural integration—the less work is required on-site.

Suitable for One- or Two-Person Installation

In high-wage markets, materials that can be handled by one or two workers significantly improve cost efficiency.

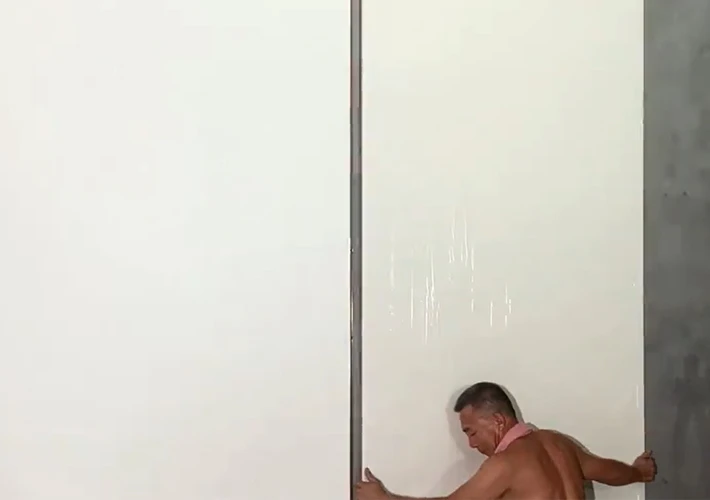

Wall Panel Systems: One of the Most Labor-Efficient Solutions

Wall panel systems, such as WPC and SPC wall panels, have become increasingly popular in overseas projects because they directly address labor challenges.

Why Wall Panels Are Preferred Over Traditional Finishes

Compared with traditional wall treatments like plastering, tiling, or stone installation, wall panels:

- Require fewer installation steps

- Avoid wet construction

- Provide consistent visual results

Key Labor-Saving Advantages

- Panels can be installed directly over existing walls, ideal for renovation projects

- Click-lock, tongue-and-groove, or batten systems simplify installation

- Factory-cut standard sizes reduce on-site processing

- Two workers can install 30–50 square meters per day under normal conditions

Typical Applications

- Hotels and serviced apartments

- Residential developments

- Commercial interiors

- Modular or prefabricated buildings

In overseas projects, wall panels are valued not only as materials but as time-saving systems.

Lightweight Decorative Sheets as Alternatives to Stone and Tile

Natural stone and ceramic tiles are increasingly avoided in overseas projects due to their labor intensity.

Why Traditional Stone Finishes Are Becoming Less Popular

- Heavy weight increases handling difficulty

- Cutting and installation require highly skilled labor

- Installation speed is slow and error-prone

Advantages of Lightweight Decorative Sheets

Materials such as PVC-based decorative sheets offer:

- Much lower weight, making handling easier

- Large-format panels that cover more area quickly

- Simple adhesive or mechanical fixing systems

These materials allow overseas projects to achieve stone-like aesthetics with significantly reduced labor input.

Project-Level Value

The main advantage is not just lower material cost, but:

Lower installation time, fewer skilled workers, and more predictable project schedules.

Composite Decorative Panels for Fast-Track Interior Projects

In hotel, apartment, and commercial interior projects, time is often more valuable than material price.

Challenges in High-End Interior Fit-Outs

- Tight schedules

- High aesthetic expectations

- Limited skilled labor availability

Why Composite Decorative Panels Save Labor

- Factory-finished surfaces eliminate on-site painting or polishing

- Integrated structures reduce installation layers

- Modular installation systems minimize rework

These materials are particularly suitable for:

- Hotel lobbies and corridors

- Public areas of residential buildings

- Retail and office spaces

They allow developers to maintain design consistency while controlling labor costs.

Systemized and Modular Construction: The Ultimate Labor-Saving Trend

In markets with extremely high labor costs, such as Australia, Northern Europe, Japan, and parts of the U.S., modular construction and systemized building solutions are becoming mainstream.

What Modular Construction Really Means

- Walls are pre-assembled in factories

- Finishes are integrated before delivery

- On-site work focuses on assembly rather than construction

Material Selection Changes Completely

In modular systems, materials must be:

- Lightweight

- Dimensionally stable

- Highly standardized

- Suitable for factory production

This explains why composite panels, integrated wall systems, and prefabricated components are increasingly used in overseas projects.

Conclusion: In Overseas Projects, Choosing Materials Means Buying Time

As labor costs continue to rise globally, material selection is no longer just about product price—it is about total project efficiency.

For overseas developers and contractors, the real question is:

- How many workers are needed?

- How long will installation take?

- How predictable is the construction process?

Materials that reduce labor input, simplify installation, and shorten timelines often deliver far greater value than cheaper but labor-intensive alternatives.

For hotel projects, residential developments, commercial interiors, and modular buildings, labor-saving material systems are becoming a strategic choice rather than an optional upgrade.