Table of Contents

ToggleIntroduction

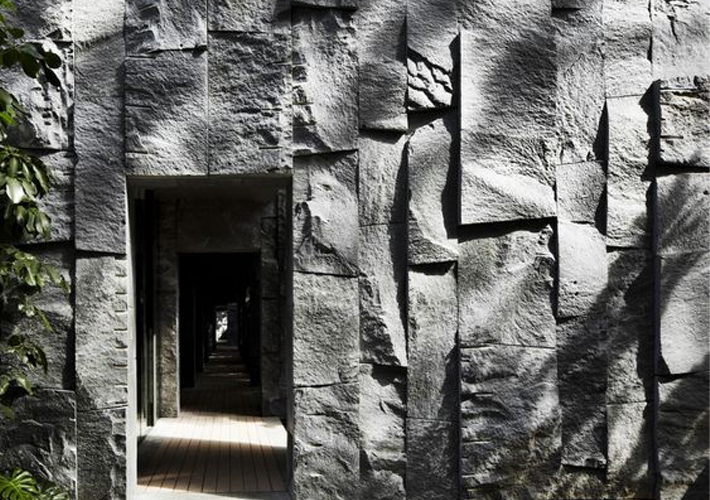

- Exterior faux stone wall panels have transformed the building materials industry by providing an affordable, lightweight, and durable alternative to natural stone.

- Market Appeal: The growth of faux stone panel use in exteriors is due to several factors, including increased interest in cost-effective, visually appealing materials that require less maintenance than natural stone.

- Key Drivers: Rising awareness of sustainable construction practices, demand for modern aesthetics in urban developments, and the need for efficient installation solutions fuel the demand for faux stone panels.

- Applications: Faux stone panels are widely used across residential facades, commercial buildings, hotels, and public infrastructure, allowing for customization that matches different architectural styles.

Growing Market Demand and Applications

- Residential Demand: Homeowners increasingly seek exterior faux stone to add sophistication and curb appeal to their homes. Faux stone offers the look of high-end stone finishes without the costs and weight constraints.

- Commercial and Hospitality: Businesses and hospitality sectors, such as hotels and resorts, use faux stone panels for a luxurious yet low-maintenance exterior. This is popular for facades, entryways, and outdoor seating areas where aesthetic appeal is critical.

- Regional Trends:North America and Europe: Growing demand for sustainable and energy-efficient building solutions, driven by both consumer preference and regulatory frameworks.Asia-Pacific: Rapid urbanization and infrastructure projects boost the demand for affordable, high-quality building materials, making faux stone panels ideal for budget-friendly construction without sacrificing aesthetics.

- Projected Growth: According to recent studies, the global faux stone panel market is expected to grow at a compound annual growth rate (CAGR) of approximately 6-8% in the next five years, with the highest demand in urbanized regions and emerging markets.

Key Technological Advancements

- Innovative Materials: Manufacturers are shifting from purely cement or resin-based panels to hybrid materials that improve flexibility, weather resistance, and UV stability. For example, polymer-based panels are more durable against harsh weather conditions and lighter for easier handling.

- 3D Printing and Texture Realism: New production techniques, like 3D printing and advanced molding, create realistic stone textures that replicate the depth and feel of natural stone. Improved pigmentation methods ensure these panels resist fading and maintain their natural look for years.

- Enhanced Thermal Insulation: Many faux stone panels are now being engineered with integrated insulation layers, enhancing energy efficiency. This means better temperature regulation, which is particularly appealing in climates with extreme temperatures.

- Quick-Fit and Interlocking Systems: To meet demands for faster installations, manufacturers have developed interlocking panel systems, which reduce installation time and improve stability, minimizing gaps and improving the visual consistency of the facade.

Sustainability and Environmental Considerations

- Eco-friendly Production: Faux stone panels typically use less energy-intensive processes than quarried stone, reducing greenhouse gas emissions. Some manufacturers now use recycled materials in production, further minimizing environmental impact.

- Recyclability and Waste Reduction: Panels made with eco-conscious materials are designed to be recycled at the end of their lifecycle, creating a circular economy that reduces waste.

- Longevity: Faux stone panels are incredibly durable, often lasting decades without showing significant wear, especially when compared to natural stone, which can erode over time. This durability reduces the need for replacements, lessening material consumption.

- Compliance with Green Building Standards: As governments introduce stricter building codes, many faux stone products are engineered to meet certifications such as LEED (Leadership in Energy and Environmental Design), a significant factor for green construction projects.

Enhanced Design Flexibility and Customization

- Wide Range of Styles and Colors: Faux stone panels are available in various designs, from rustic and classic stone to sleek, modern styles, allowing architects and builders to achieve any desired look.

- Color Consistency and Customization: Unlike natural stone, which can vary significantly in color and texture, faux stone panels allow for consistent color throughout large projects. This consistency is especially beneficial for large facades where uniformity is essential.

- Modular and Scalable: Modular panel systems allow builders to scale up or down based on the project requirements, making it easier to use faux stone in projects of all sizes, from small residential applications to extensive commercial exteriors.

Increased Demand for Cost-Effectiveness and Efficiency

- Lower Installation and Labor Costs: Faux stone panels are lighter and easier to handle than natural stone, significantly reducing labor costs. The quick-fit designs further lower costs by speeding up installation time.

- Minimal Maintenance Requirements: Faux stone panels resist moisture, mildew, and staining better than natural stone, minimizing the need for maintenance and prolonging their lifespan.

- High Return on Investment (ROI): Faux stone is typically a more affordable upfront investment compared to natural stone. Coupled with reduced maintenance and installation costs, it offers high ROI, especially for commercial projects that prioritize long-term savings.

Future Market Projections and Potential Challenges

- Projected Market Growth: According to market research, the faux stone panel industry is set to see substantial growth, with North America, Europe, and Asia-Pacific leading demand. By 2028, the market is projected to exceed $XX billion globally, driven by a surge in construction projects and eco-conscious consumers.

Potential Challenges:

- Increased Competition: As demand grows, so does competition from alternative exterior materials, such as vinyl siding, WPC cladding, and ceramic tiles. This competition pushes manufacturers to continuously innovate.

- Rising Raw Material Costs: Costs for raw materials, like resins and polymers, may fluctuate, affecting production costs and potentially pricing.

- Regulatory Constraints: Building codes in some regions might place restrictions on certain materials or manufacturing processes, necessitating compliance with fire safety and environmental standards. This will push manufacturers to adopt stricter quality controls and innovate in material formulation to meet these codes.

Conclusion

- The future of exterior faux stone wall panels looks promising, fueled by rapid advancements in material science, increasing demand for sustainable solutions, and the shift towards customizable, cost-effective building materials.

- Faux stone panels represent a compelling choice for the future of construction materials. Their appeal spans both aesthetic and functional aspects, offering the charm of natural stone with enhanced benefits that support green construction.

- As a versatile and durable solution, faux stone panels will likely continue evolving in response to market needs, solidifying their place in modern and sustainable architecture.