Table of Contents

ToggleIntroduction to UV Marble Sheets

UV marble sheets, also known as UV-coated PVC marble sheets, are a modern alternative to natural marble. These sheets are designed to replicate the luxurious appearance of natural stone while offering benefits such as lightweight properties, water resistance, affordability, and easy maintenance.

Used extensively in wall cladding, furniture surfaces, ceilings, kitchens, bathrooms, and commercial spaces, UV marble sheets have gained popularity due to their durability, aesthetic versatility, and cost-effectiveness.

This article provides a detailed analysis of UV marble sheets, covering their composition, manufacturing process, properties, advantages, and applications.

Composition of UV Marble Sheets

UV marble sheets are multi-layered composite materials that combine various elements to achieve superior performance. Below is a breakdown of each layer and its function:

2.1 Base Material (Core Layer)

The core layer provides the sheet with structural integrity and mechanical strength. Two common materials are used:

2.1.1 PVC (Polyvinyl Chloride) Core

- PVC is the most common core material used in UV marble sheets.

- It is a lightweight, waterproof, and flame-retardant plastic material.

- Provides resistance to moisture, termites, and chemical corrosion.

- Eco-friendly options use lead-free and formaldehyde-free PVC for sustainability.

2.1.2 WPC (Wood-Plastic Composite) Core

- WPC is a hybrid material made from wood fibers and PVC resin.

- Offers a stronger, more rigid structure compared to pure PVC.

- Enhances environmental friendliness by incorporating recycled wood and plastic.

- More resistant to deformation compared to standard PVC.

2.2 Decorative Film (Marble Pattern Layer)

- This layer consists of a high-resolution printed film that replicates the natural veining and texture of real marble.

- The printing process uses advanced digital technology to ensure high precision and realistic visuals.

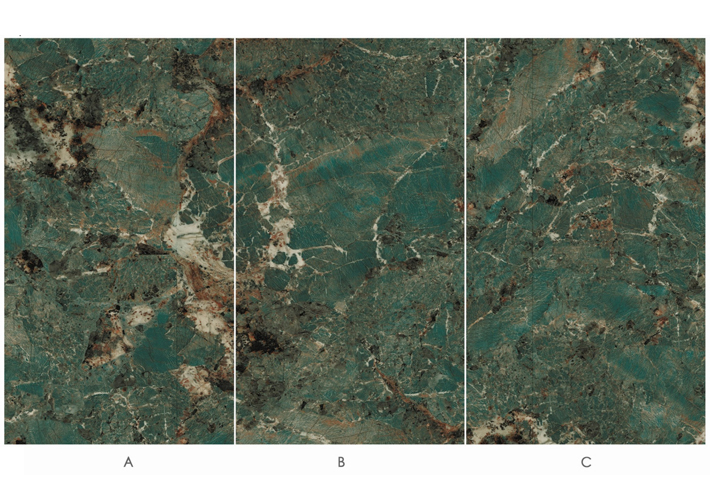

- Available in various marble designs such as Carrara, Calacatta, Emperador, and Onyx.

- Ensures color consistency and provides design flexibility.

2.3 UV Coating Layer

The UV coating layer is a crucial component that enhances surface durability, scratch resistance, and glossiness. This layer includes:

- UV-cured resin coating that creates a high-gloss or matte finish.

- Protects against fading, discoloration, and surface wear.

- Improves stain resistance, making the sheet easy to clean.

- Some sheets include an anti-bacterial UV coating for hygienic applications.

2.4 Protective Film Layer (Optional)

- A temporary plastic film may be added during production to protect the sheet from scratches and damage before installation.

- This film is peeled off after installation to reveal the glossy, finished surface.

Manufacturing Process of UV Marble Sheets

The production of UV marble sheets involves multiple high-precision manufacturing steps to ensure quality and durability.

Step 1: Raw Material Preparation

- PVC resin, WPC powder, stabilizers, and additives are carefully measured and mixed to form the core material.

- If using WPC, wood fiber and plastic granules are blended and melted together.

Step 2: Core Layer Extrusion

- The mixture is fed into an extrusion machine, where it is heated, melted, and shaped into flat sheets.

- The sheet thickness is controlled precisely, usually between 2mm and 6mm.

Step 3: Application of Decorative Film

- The marble-patterned decorative film is laminated onto the surface of the extruded PVC or WPC sheet using high-pressure rollers.

- Advanced heat transfer or cold lamination techniques are used to ensure proper adhesion.

Step 4: UV Coating Process

- The laminated sheets pass through UV coating machines, where they receive a protective resin layer.

- This layer is cured under ultraviolet (UV) light, forming a scratch-resistant, glossy, or matte finish.

- The UV coating thickness can be adjusted for different durability levels.

Step 5: Cutting and Finishing

- The large sheets are cut into standard sizes (e.g., 1220mm x 2440mm) or customized dimensions.

- Edge treatments and polishing are done to enhance smoothness and quality.

Step 6: Quality Inspection and Packaging

- Each sheet undergoes strict quality checks for surface defects, strength, and coating uniformity.

- Sheets are stacked, protected with film, and packaged for shipment.

Properties and Advantages of UV Marble Sheets

4.1 Key Properties

- Thickness: Usually between 2mm – 6mm

- Weight: Lighter than natural marble (about 3-4kg/m²)

- Surface Finish: Glossy, semi-gloss, or matte

- Standard Size: 1220mm x 2440mm, customizable sizes available

- Waterproof & Moisture-Proof: Ideal for bathrooms and kitchens

- Scratch Resistance: Due to UV-cured protective layer

- Heat Resistance: Can withstand moderate heat but should not be exposed to open flames

4.2 Major Advantages

✅ Lightweight – Easier to transport and install compared to real marble.

✅ Cost-Effective – Provides a luxurious marble look at a fraction of the price.

✅ Easy to Install – Can be installed using glue, nails, or screws, reducing labor costs.

✅ Eco-Friendly Options – Available in lead-free, formaldehyde-free, and recyclable materials.

✅ Low Maintenance – Resistant to stains, moisture, and easy to clean.

✅ Wide Design Choices – Offers various marble patterns to suit modern and classic interiors.

Applications of UV Marble Sheets

UV marble sheets are versatile and widely used in residential, commercial, and industrial settings:

5.1 Home Interiors

- Wall Panels & Cladding – Living rooms, bedrooms, and hallways

- Ceiling Panels – Adds a luxury feel to ceilings

- Bathroom Walls – Waterproof properties make them ideal for wet areas

- Kitchen Backsplashes – Stain-resistant and easy to clean

5.2 Commercial Spaces

- Hotels & Restaurants – Used for feature walls, reception areas, and dining spaces

- Office Interiors – Provides a modern and elegant appearance

- Retail Stores – Enhances showrooms, counters, and shelving units

5.3 Furniture & Cabinetry

- Wardrobe Panels – Offers a high-end appearance

- TV Background Walls – Popular for entertainment units

- Tabletops & Counters – Durable, stylish, and cost-effective

Conclusion

UV marble sheets are a modern, cost-effective, and versatile alternative to natural stone. Their lightweight design, durability, waterproof properties, and aesthetic appeal make them a top choice for both homeowners and commercial designers.

With a wide range of colors, patterns, and finishes, UV marble sheets continue to revolutionize the interior decoration industry, providing a luxurious marble look without the drawbacks of real stone.

👉 If you are a wholesaler or interior contractor, investing in UV marble sheets can offer high market demand and profitability.