The production process for PVC marble sheets typically involves several steps, including material preparation, mixing, extrusion, cooling, embossing, cutting, and quality control. Here’s a general overview of the process:

- Material Preparation: PVC resin, calcium carbonate (as filler), stabilizers, pigments, and other additives are weighed and prepared according to the desired formulation.

- Mixing: The raw materials are mixed together in a high-speed mixer. This ensures uniform distribution of additives and pigments throughout the PVC compound.

- Extrusion: The mixed PVC compound is then fed into an extruder. Inside the extruder, the compound is heated and forced through a die, forming a continuous sheet of PVC material. This sheet is typically of uniform thickness and width.

- Cooling: After extrusion, the PVC sheet is cooled using cooling rollers or a water bath. Cooling is essential to set the shape and dimensions of the sheet.

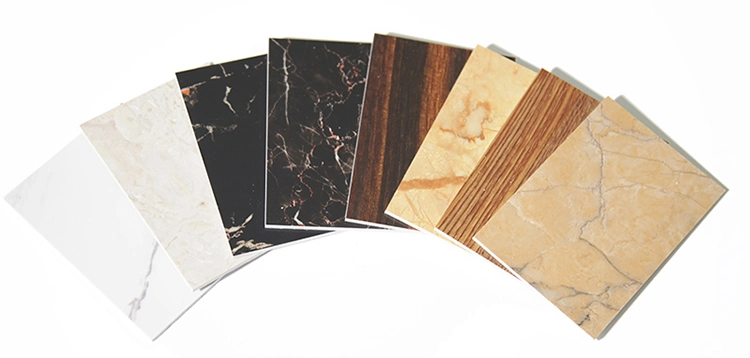

- Embossing: To create the marble effect, the cooled PVC sheet may undergo embossing. This process involves passing the sheet through embossing rollers or plates, which imprint a pattern onto the surface to simulate the look of natural marble.

- Cutting: Once embossing is complete, the PVC sheet is cut to the desired dimensions. This can be done using cutting machines or other equipment to produce sheets of various sizes.

- Quality Control: Throughout the production process, quality control measures are implemented to ensure that the PVC marble sheets meet the required standards. This may involve visual inspections, measurements of thickness and dimensions, and testing for physical properties such as strength and durability.

- Packaging and Storage: Finally, the finished PVC marble sheets are packaged and prepared for shipping. They may be stacked, wrapped, or boxed for protection during transportation and storage.

It’s important to note that specific details of the production process can vary depending on factors such as the equipment used, the desired characteristics of the final product, and the manufacturing standards of the factory. Additionally, environmental considerations and regulatory requirements may influence certain aspects of the production process, such as the handling and disposal of waste materials.

Shandong Compass Decor Material Co.,Ltd is a company that focuses on the research, development and production of all kinds of fashionable,latest and best-selling decoration materials. Our main products: LVT flooring,SPC flooring,WPC wall panel,WPC decking,PVC/WPC sheet, PVC/WPC Skirting and all kinds of related accessories. We export to 50 countries including North America, Western Europe,Southeast Asia, Middle East, Australia, etc. Excellent product quality and perfect pre-sales and after-sales service system make our products well received by customers all over the world.We are well-known in the industry and have many years of export experience,Our factory are located in Linyi city , Shandong province .Qingdao port is very near by Linyi with convenient transportation access .

We have strong production capabilities and can flexibly plan production based on customer orders, while ensuring production cycles and delivery times.If you are interested in our products, please feel free to inquire!