PVC foam boards come in a variety of dimensions to suit different applications. Here are some common sizes:

Thickness:

PVC foam boards are available in a wide range of thicknesses, typically from 1 mm to 30 mm. Here are some common options:

- 1 mm

- 2 mm

- 3 mm

- 4 mm

- 5 mm

- 6 mm

- 8 mm

- 10 mm

- 12 mm

- 15 mm

- 18 mm

- 20 mm

- 25 mm

- 30 mm

Standard Sheet Sizes:

The most commonly available sheet sizes for PVC foam boards are:

- 1220 mm x 2440 mm (4 ft x 8 ft)

- 1560 mm x 3050 mm (5 ft x 10 ft)

- 2050 mm x 3050 mm (6.5 ft x 10 ft)

These standard sizes cover most general applications. However, some manufacturers might offer additional standard sizes or variations depending on their production capabilities.

Custom Sizes:

Many suppliers offer custom cutting services, allowing you to order PVC foam boards in specific dimensions to suit your project needs. This is particularly useful for large-scale industrial projects or unique design requirements.

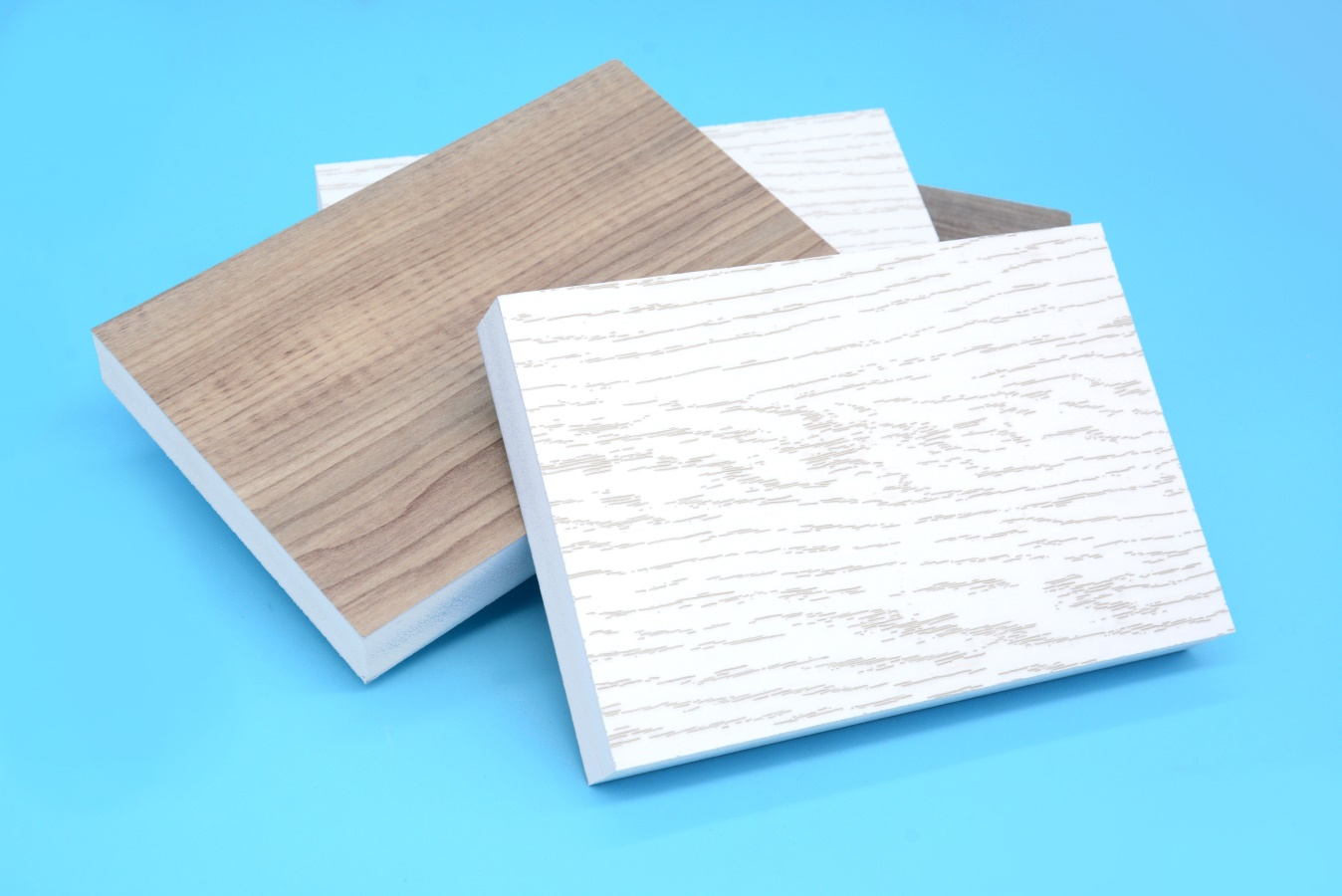

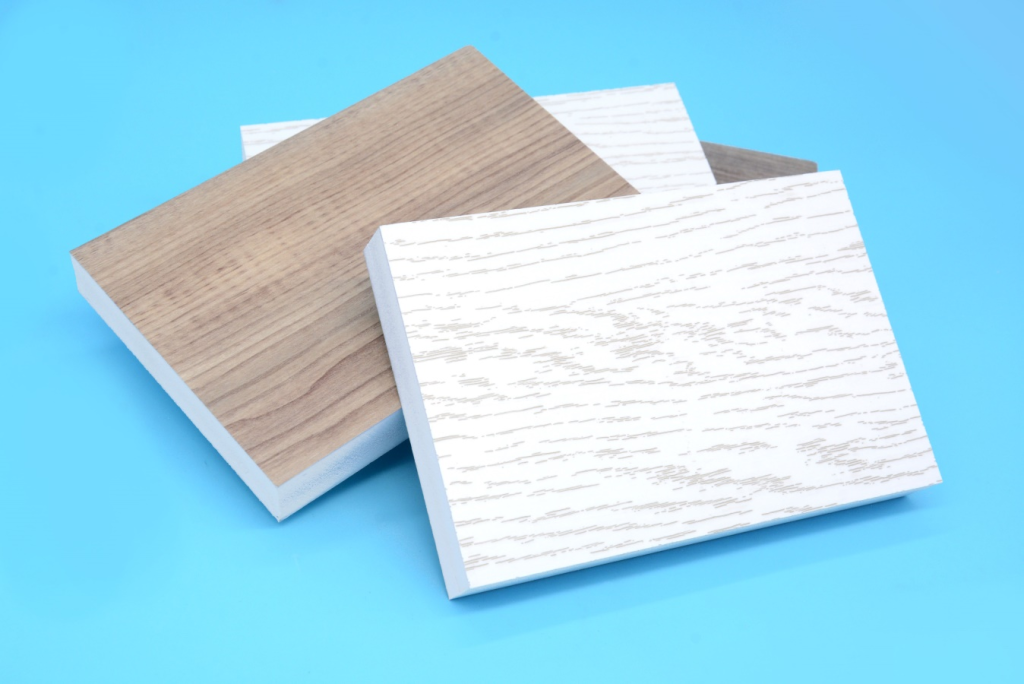

Surface Finish:

PVC foam boards come with different surface finishes, which can impact their suitability for various applications:

- Matte Finish: Ideal for printing, signage, and displays.

- Glossy Finish: Provides a smooth, shiny surface, often used for decorative purposes.

- Embossed Finish: Offers textured surfaces for specific aesthetic or functional requirements.

Color Options:

While white is the most common color for PVC foam boards, they are also available in a variety of other colors, including:

- Black

- Grey

- Red

- Blue

- Green

- Yellow

Custom colors can also be requested from some manufacturers, especially for large orders.

Density:

PVC foam boards are categorized based on their density, which affects their weight, strength, and durability. Common density ranges include:

- Low-Density (0.45-0.55 g/cm³): Lighter, easier to handle and install, suitable for indoor applications like signage and displays.

- Medium-Density (0.55-0.65 g/cm³): Balanced properties, ideal for both indoor and outdoor use.

- High-Density (0.65-0.80 g/cm³): Heavier, more robust, suitable for applications requiring higher strength and durability, like furniture and construction.

Applications:

PVC foam boards are versatile and used in various industries, including:

- Advertising and Signage: Due to their smooth surface and ease of printing.

- Construction: As lightweight alternatives to wood or metal.

- Furniture Making: For lightweight, durable furniture.

- Interior Design: Used in wall cladding, partitions, and decorative elements.

- Exhibition Stands: Lightweight and easy to assemble and disassemble.

- DIY Projects: For custom craft and home improvement projects.

Advantages:

- Lightweight: Easy to transport and install.

- Durable: Resistant to moisture, chemicals, and UV radiation.

- Versatile: Can be cut, shaped, and painted.

- Cost-effective: Provides a balance of performance and affordability.

Disadvantages:

- Thermal Expansion: Can expand or contract with temperature changes.

- Strength: Less rigid than some other materials, which might not be suitable for high-load applications.

For specific projects, it’s best to consult with suppliers or manufacturers to get the most suitable dimensions and properties for your needs.