UV sheets, also known as UV-coated panels, are gaining popularity in various industries due to their durability, aesthetic appeal, and environmental benefits. Here are some key trends likely to shape the future development of UV sheets:

1. Technological Advancements

- Improved Coating Techniques: Continued innovation in UV curing technology will lead to more efficient and effective curing processes. This will result in UV sheets with enhanced surface hardness, better adhesion, and greater resistance to wear and tear. The development of faster curing processes will also reduce production times and costs.

- Advanced Printing Technologies: Digital printing advancements will enable high-resolution, full-color graphics to be applied to UV sheets with precision. This will allow for more complex and customizable designs, meeting diverse consumer and industry needs.

- Nanotechnology: Incorporation of nanomaterials in UV coatings can enhance properties such as scratch resistance, antimicrobial effects, and UV stability, making UV sheets suitable for a broader range of applications.

2. Sustainability

- Eco-friendly Materials: With increasing environmental awareness, manufacturers will focus on developing UV sheets using sustainable and recyclable materials. This includes the use of bio-based resins and reducing the reliance on volatile organic compounds (VOCs) in coatings.

- Energy Efficiency: UV curing processes are already energy-efficient compared to traditional curing methods. Future developments will likely focus on further reducing energy consumption during production, making UV sheets an even greener choice.

- Circular Economy: There will be a push towards creating UV sheets that are part of a circular economy, where end-of-life products can be recycled or repurposed into new products, reducing waste and resource consumption.

3. Market Expansion

- Diversified Applications: UV sheets will see increased use across various sectors, including automotive, electronics, furniture, and construction. Their durability, aesthetic versatility, and resistance to environmental factors make them suitable for a wide range of uses.

- Consumer Electronics: The electronics industry, in particular, will benefit from UV sheets for creating durable, high-gloss finishes on devices like smartphones, tablets, and laptops.

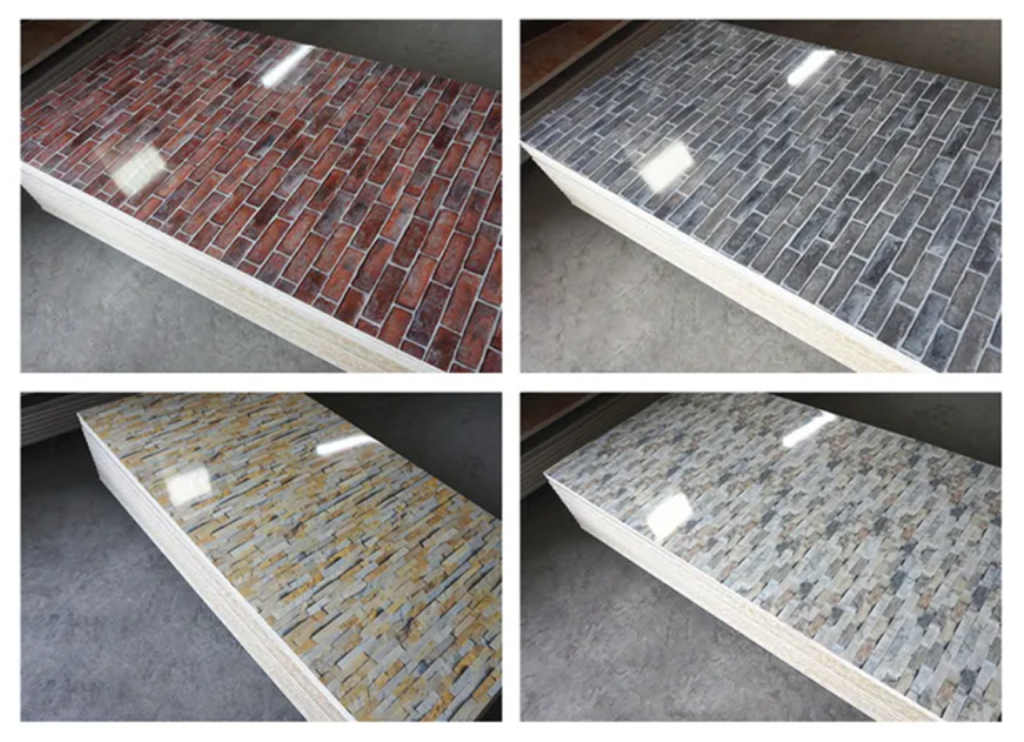

- Interior Design and Architecture: UV sheets will become more prevalent in interior design and architectural applications due to their ability to mimic natural materials like wood and stone, combined with superior performance characteristics.

4. Enhanced Performance Characteristics

- Functional Coatings: UV sheets with additional functional properties, such as anti-fingerprint, antimicrobial, and self-cleaning surfaces, will be developed to meet specific industry needs.

- Weather Resistance: Improved UV stability will ensure that UV sheets retain their color and finish even when exposed to harsh outdoor conditions, making them suitable for exterior applications.

5. Customization and Personalization

- On-Demand Manufacturing: Advances in digital manufacturing and printing will allow for on-demand production of customized UV sheets. This will cater to individual preferences and niche markets, providing unique and personalized products.

- Mass Customization: Manufacturers will adopt mass customization strategies, allowing for large-scale production of UV sheets with customizable features, balancing the benefits of mass production with the need for personalized products.

6. Integration with Smart Technologies

- Smart Surfaces: UV sheets integrated with smart technologies, such as touch-sensitive surfaces and embedded sensors, will open up new possibilities for interactive and multifunctional surfaces in various applications.

- IoT Integration: The integration of UV sheets with Internet of Things (IoT) technologies will enable smart applications in homes, offices, and public spaces, enhancing user experiences and functionality.

The future of UV sheets looks promising, with continuous advancements in technology, sustainability, and market applications driving their growth and development.